In the field of electrical connections, reliability begins with every detail—and crimp connectors are a crucial part of that. Whether in industrial equipment, automotive wiring harnesses, or household appliances, proper crimp connections ensure stable signal and power transmission. This article will systematically explain crimp connectors types, wiring methods, and common issues to help you make more informed purchasing decisions.

What Is A Crimping Connector?

A crimp connector is an electrical component that permanently and securely connects metal terminals to wire conductors through physical compression. It requires no soldering; instead, high pressure generated by a specialized tool deforms the terminal metal, causing it to tightly engage with the wire core, forming a low-resistance, high-mechanical-strength connection. This connection method is efficient and consistent, making it ideal for mass production and applications requiring high reliability.

Crimp Terminal Wire Connector Types

Understanding the different types of connectors is the first step to selecting the right one. Here are some core categories:

Insulated Terminals

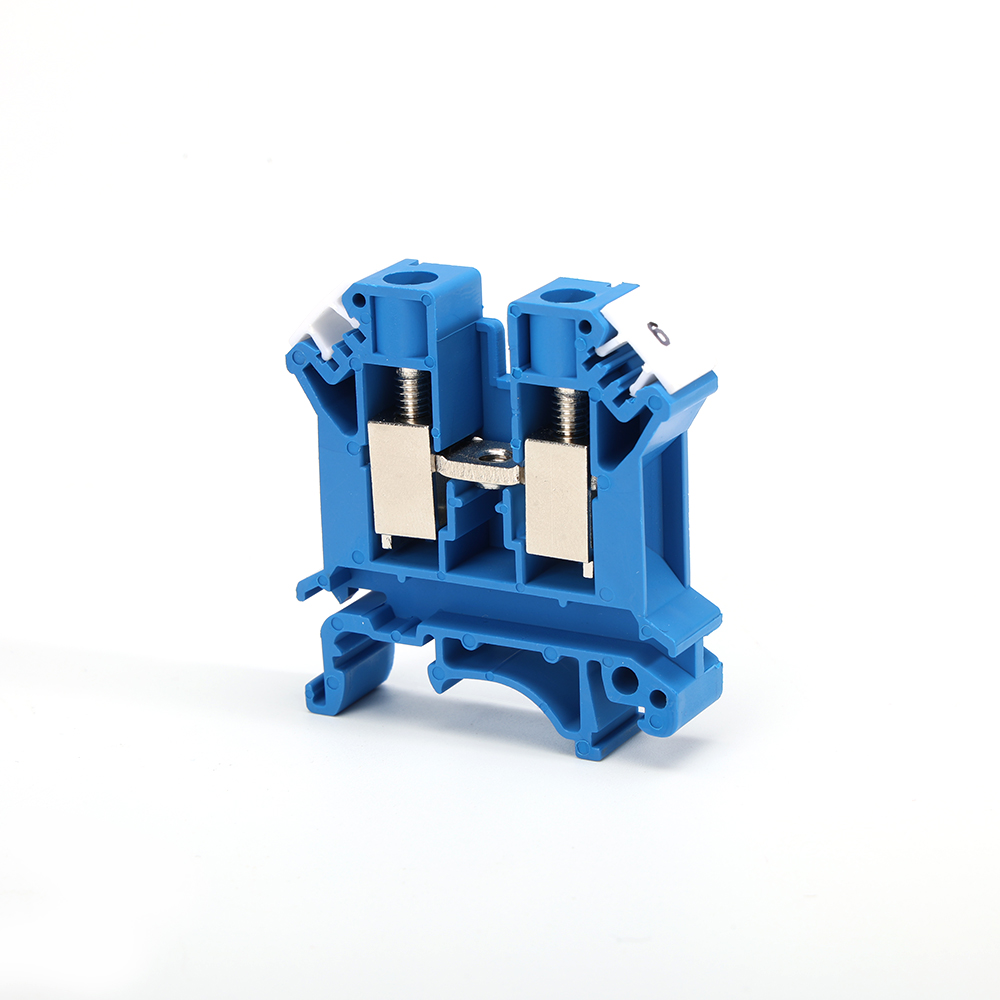

These terminals have a metal sleeve encased in a layer of colored plastic (usually PVC or nylon), with colors typically corresponding to different wire gauges. The insulation layer provides electrical insulation and some mechanical protection.

Ring terminals: Used for screw fixing, prevents rotation, and offers the most reliable connection.

Fork terminals: Do not require complete screw removal during installation, facilitating disassembly and maintenance.

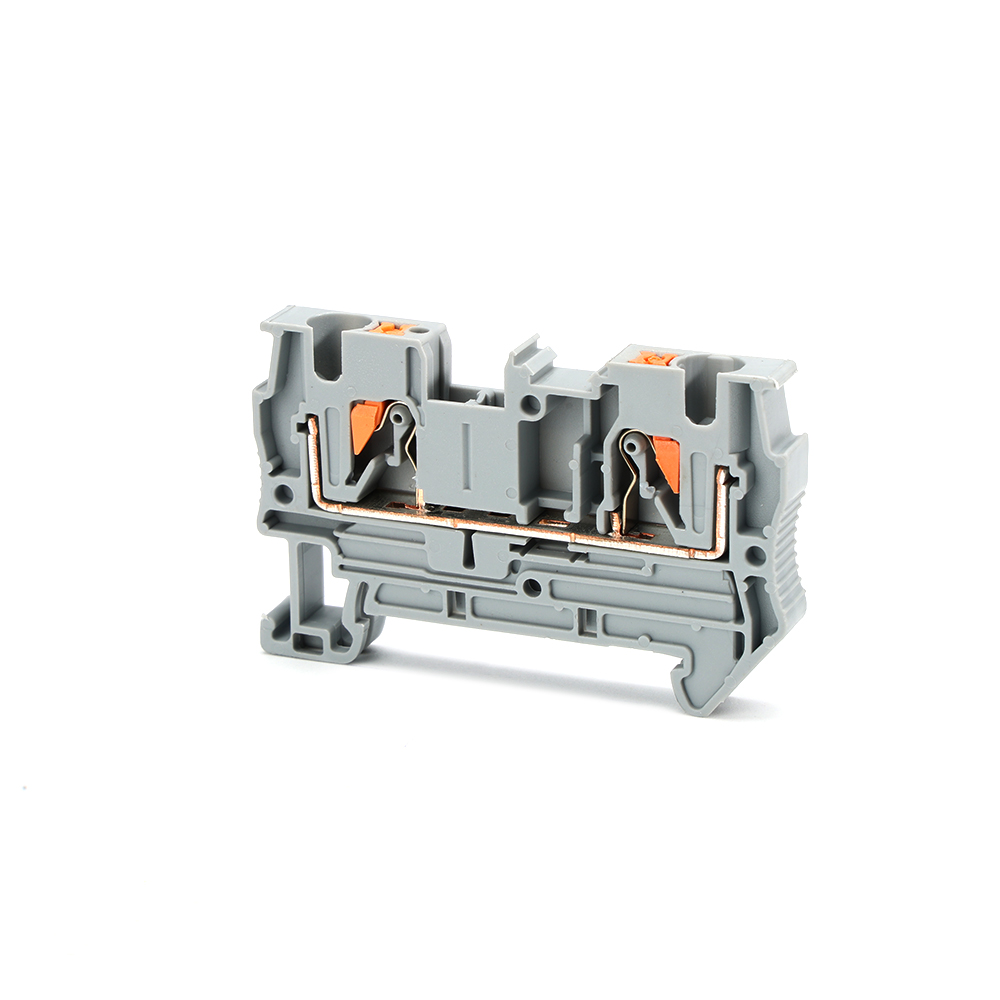

Pin/plate terminals: Used for plug-in connections, commonly found in terminal blocks and controllers.

Non Insulated Terminals

These are bare metal terminals, typically made of copper, brass, or aluminum, and may require additional heat-shrink tubing or insulating sleeves.

Advantages: More compact size, generally lower cost, suitable for use in confined spaces or applications requiring subsequent overall insulation.

Wire To Connector

Used to connect two or more wires together.

Closed-end crimp cap: Permanently sealed connection.

Butt splice connector: Connects two wire ends together.

T-splice: Used to branch lines from the main line.

Other Professional Types

This includes RF connectors for coaxial cables, automotive-grade waterproof connectors, and special crimp terminals for circuit board leads.

Crimp Connector Type Quick Reference Table

| Type | Main Subclasses | Typical Applications | Key Advantage |

| insulated terminal | Circular, fork shaped, sheet shaped | Control cabinet, power wiring, internal equipment | Equipped with insulation, safe installation, and clear labeling |

| Non insulated terminal | Naked circular, bare fork shaped | High temperature environment, requiring overall insulation | Low cost, small size, flexible applicability |

| Wire to wire splicer | Crimp cap, connecting pipe | Wire extension, branching, and maintenance | No welding required, the connection is firm and neat |

| Professional connectors | Coaxial terminal, waterproof type | Communication, automotive, outdoor equipment | Meet specific electrical or environmental requirements |

Tools And Materials

To do a good job, one must first have the right tools. A reliable set of tools is fundamental to ensuring high-quality crimping.

Professional Crimping Pliers: This is the core tool. Choosing the right dies for the terminals is crucial. For example, Westlec’s matching crimping tools ensure optimal crimping results.

Wire Stripper: Precisely strips the insulation without damaging the conductor.

Wire Diameter Gauge: Accurately measures wire diameter to select the correct terminal size.

High-Quality Terminals: Crimp on wire splice is recommended to choose brands like Westlec, whose products offer better guarantees in copper purity, plating quality, and dimensional accuracy, eliminating the possibility of poor contact or corrosion from the outset.

How To Wire Crimp Connectors

Following standard procedures is the guarantee of a perfect connection.

Preparation Work

Verify compatibility: Ensure that the specifications of the terminal, wire gauge, and crimping tool die are completely compatible.

Strip insulation: Use a wire stripper to remove an appropriate length of insulation (usually based on the terminal tube length). Expose fresh, undamaged stranded wire cores.

Standard Crimping Steps

Insertion: Fully insert the exposed wire core into the terminal’s metal sleeve, ensuring the tip is flush with the sleeve opening and the insulation layer is below the insulation sleeve.

Positioning: Correctly place the terminal into the corresponding die slot of the crimping pliers.

Crimping: Firmly and steadily grip the tool handle until it fully closes or automatically releases (ratchet mechanism).

Inspection: After crimping, gently pull the wire and terminal to check for a secure connection.

Quality Inspection Standards

A qualified crimp joint should possess the following characteristics:

High mechanical strength: The wire cannot be easily pulled out.

Good electrical conductivity: Low contact resistance.

Neat appearance: The crimped area has a uniform shape, without excessive deformation or cracking. Insulation (if applicable) should not be damaged.

Common Errors And Avoidance Methods

Error: Wire diameter does not match the terminal.

Avoid: Always use a diameter gauge and refer to the manufacturer’s specifications.

Error: Wire core not fully inserted or excessive stripping.

Avoid: Accurately measure the stripping length and ensure the wire core is visible through the terminal inspection hole (if present) after insertion.

Error: Using the wrong crimping die or tool.

Avoid: Use the recommended or original tools for different brands and series of terminals. For example, in several industrial projects at Westlec, using matching tools reduced the failure rate by more than 70%.

Error: Over- or under-crimping.

Avoid: Use professional crimping pliers with a ratchet mechanism, which ensures consistent crimping force every time.

FAQ

In Which Fields Is The Crimping Connector Applied?

Its applications are extremely wide, including automobile manufacturing and repair, industrial automation control cabinets, home appliances, aerospace, rail transportation, communication equipment, and new energy (such as photovoltaic junction boxes). It can be found in almost any situation requiring reliable and efficient wiring connections.

Why Choose Crimping Connection?

Crimping offers advantages such as high speed, high consistency, no heat source required, no harmful gas generation, high mechanical strength of the connection points, and stable electrical resistance. It is particularly suitable for large-scale production and on-site construction, ensuring that the quality of each connection point meets standards.

The Difference In Crimping Between Multi Strand Wires And Solid Wires

Stranded wires are more common; during crimping, the metal sleeve tightly engages the multiple strands, forming a strong mechanical interlock. When crimping single-core solid wires, the holding force mainly relies on the deformation of the sleeve. The key is to select terminals specifically designed for the corresponding wire type and ensure that the crimping die can apply appropriate pressure to prevent the cable from cutting or loosening.

Conclusion

Choosing the appropriate Crimp Terminal Wire Connector Types and mastering the correct How To Wire Crimp Connectors are fundamental skills for ensuring the long-term stable operation of electrical systems. From accurate selection and professional tools to standardized operation, every step requires meticulous attention.

As a purchaser, choosing a supplier like Westlec, which provides a full range of high-quality crimp connectors and related solutions, not only ensures reliable products but also access to professional technical support, fundamentally improving the quality and market competitiveness of your final products. After all, the best connections are those whose faults are never noticed.