Briefly Explain What Terminal Blocks Are

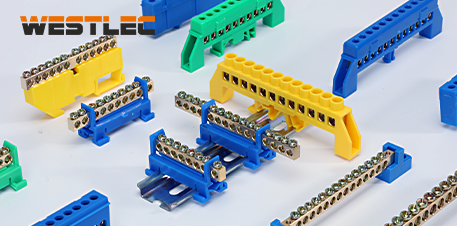

A terminal block is an electrical connector that allows multiple wires to be safely joined together within a single system. They are widely used in control panels, machinery, power distribution units, and industrial automation equipment to ensure secure and organized wiring.

Highlight Why Proper Selection Matters

Choosing the right terminal block is critical for system reliability and safety. An improper terminal block selection can lead to overheating, loose connections, or even equipment failure. By following a terminal block selection guide, engineers and technicians can ensure optimal performance, compliance with safety standards, and long-term durability.

1.What is a Terminal Block?

A terminal block is a modular device that connects two or more wires together. It typically consists of an insulating body, conductive metal parts, and mounting features. Terminal blocks serve as the interface between incoming and outgoing circuits, allowing for easy wiring, secure connections, and organized maintenance.

2.Types of Terminal Blocks

When exploring terminal block types, it’s important to understand their variations based on application and design:

Feed-through terminal blocks – For connecting two wires directly.

Ground terminal blocks – Provide safe grounding connections.

Fuse terminal blocks – Include built-in fuses for circuit protection.

Disconnect terminal blocks – Allow quick disconnection for testing and maintenance.

Multi-level terminal blocks – Stack multiple circuits vertically to save space.

Pluggable terminal blocks – Enable quick installation and removal of wires.

Selecting the right type depends on application requirements, available space, and safety needs.

3.Key Factors in Terminal Block Selection

Electrical Ratings (Voltage, Current)

Ensure the terminal block supports the system’s maximum operating voltage and current. Always add a safety margin beyond the calculated requirement.

Wire Size Compatibility

Check the terminal block’s clamping range to match the conductor cross-section. Using the wrong size may cause loose connections or overheating.

Mounting Options

Terminal blocks can be mounted on DIN rails, PCBs, or directly onto panels. Choose a mounting method that matches your installation environment and maintenance needs.

Environmental Conditions and Safety Standards

Consider factors like operating temperature, humidity, vibration, and exposure to chemicals. Compliance with international standards (IEC, UL, CSA) ensures safe and reliable operation.

4. Terminal Block Selection Guide (Step-by-Step)

| Step | Focus | Details |

| Step 1: Define Application Requirements | Application | Identify usage scenario: industrial machinery, building wiring, or power distribution. |

| Step 2: Check Voltage, Current, and Wire Size | Electrical Matching | Match terminal block ratings with system’s voltage, current, and conductor specifications. |

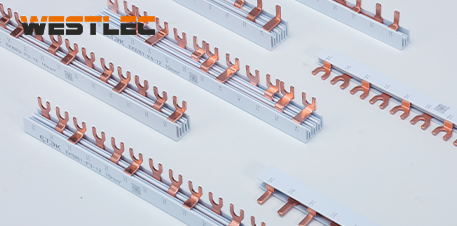

| Step 3: Select the Right Connection Type | Connection Technology | Screw connection: Reliable, widely used. |

| Push-in connection: Tool-free, time-saving. | ||

| Spring clamp: Vibration resistant. | ||

| Step 4: Choose Mounting Style | Installation | Options include DIN rail, PCB, or panel-mounted designs. |

| Step 5: Verify Environmental and Safety Standards | Standards & Materials | Ensure compliance with UL, IEC, or regional standards; choose materials suitable for operating conditions. |

Step 1: Define Application Requirements

Identify where the terminal block will be used—industrial machinery, building wiring, or power distribution.

Step 2: Check Voltage, Current, and Wire Size

Match the block’s ratings with your system’s electrical requirements and conductor specifications.

Step 3: Select the Right Connection Type

Common connection technologies include:

Screw connection – Reliable and widely used.

Push-in connection – Tool-free and time-saving.

Spring clamp – Vibration resistant.

Step 4: Choose Mounting Style

Decide between DIN rail, PCB, or panel-mounted designs depending on installation requirements.

Step 5: Verify Environmental and Safety Standards

Ensure compliance with UL, IEC, or other regional standards. Select materials rated for your system’s operating conditions.

5.Applications of Terminal Blocks

Terminal blocks are versatile and can be found in:

Industrial automation systems

Power distribution panels

Renewable energy installations

Transportation and railway systems

Building and facility management systems

6.FAQs

Q1: What is the most common type of terminal block?

The most widely used type is the feed-through terminal block, suitable for connecting two conductors.

Q2: What is the difference between screw and push-in connections?

Screw connections require tightening with a tool, while push-in connections allow tool-free wiring, saving time during installation.

Q3: How do I know if my terminal block meets safety standards?

Check for certifications such as UL, IEC, or CSA, and review manufacturer specifications for temperature and voltage ratings.

Conclusion

Proper terminal block selection is essential for ensuring safety, reliability, and long-term system performance. By following this terminal block selection guide, engineers can confidently choose the right terminal block types for their applications. Always consider electrical ratings, wire compatibility, mounting style, and environmental conditions to achieve the best results.