Introduction

Busbar insulators are essential components in electrical systems, providing support, insulation, and protection for busbars. These insulators prevent electrical faults, improve safety, and ensure reliable power distribution in high-voltage and industrial environments. Understanding their types, materials, and applications is crucial for engineers, electricians, and system designers.

1.What Is a Busbar Insulator

1.What Is a Busbar Insulator

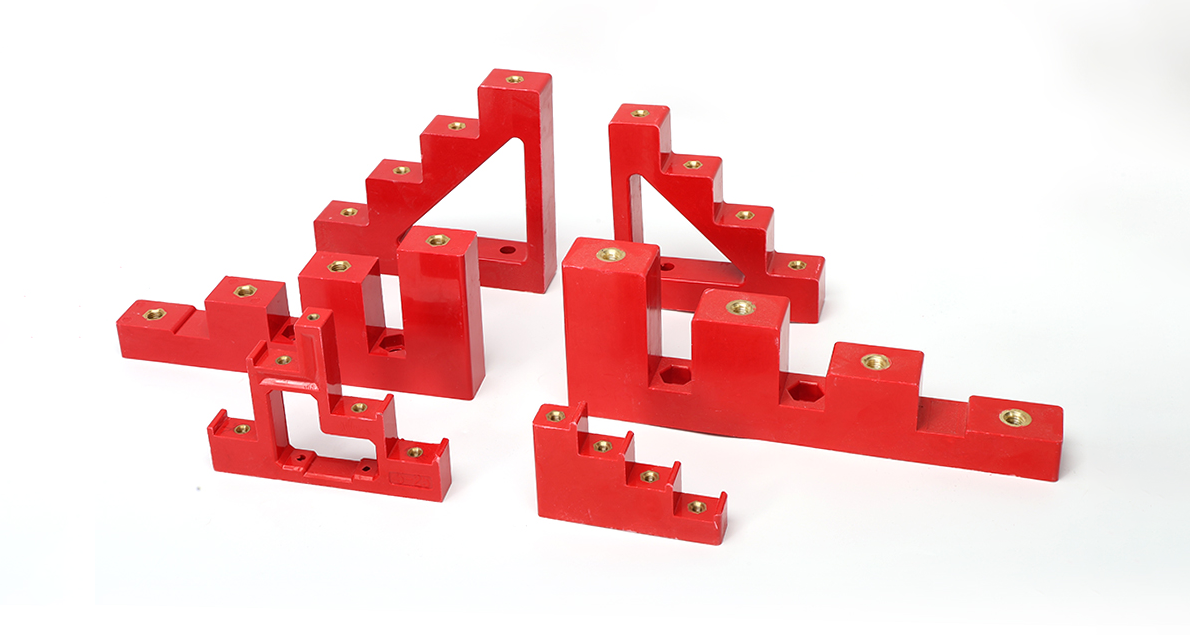

1-1 Definition of Busbar Insulator

A busbar insulator is a non-conductive component that supports and electrically isolates busbars. It prevents unintended contact between conductive parts and maintains the stability and efficiency of the electrical system.

1-2 Busbar Insulator Function

Busbar insulators serve three main purposes:

Support: Physically hold busbars in place.

Insulation: Prevent electrical current from flowing to unintended paths.

Protection: Reduce risks of short circuits, equipment damage, and fire.

1-3 Safety Risks Without Insulators

Without proper busbar insulation:

Short circuits and electrical faults can occur.

Equipment and personnel may be at risk of electric shock.

System reliability and longevity are significantly reduced.

2.Types of Busbar Insulators

2-1 Busbar Insulator Types

Common busbar insulator types include:

Post Insulators: Vertical supports for medium and high-voltage busbars.

Pin Insulators: Mounted on pins for rigid support in low to medium voltage systems.

Suspension Insulators: Hang from structures for high-voltage lines, allowing flexibility and load support.

Composite Insulators: Made from polymer or composite materials, offering lightweight, flexible, and weather-resistant solutions.

2-2 Key Features and Applications of Each Type

Post: High mechanical strength, used in substations.

Pin: Compact, stable, used in distribution lines.

Suspension: Flexible, ideal for long-span high-voltage lines.

Composite: Resistant to corrosion and pollution, used in outdoor and harsh environments.

3.Busbar Insulation Materials

3-1 Busbar Insulation Materials

Common insulation materials include:

Ceramic: High mechanical strength, heat-resistant, durable.

Glass: Transparent, high insulation capability, UV-resistant.

Composite: Lightweight, corrosion-resistant, flexible.

3-2 How Materials Affect Voltage, Heat, and Corrosion Resistance

Ceramic: Excellent voltage withstand and thermal resistance; brittle under mechanical stress.

Glass: Strong electrical insulation, visible monitoring; prone to breakage.

Composite: Handles harsh environments, resistant to weathering and pollution; may degrade over long-term UV exposure.

3-3 Choosing the Right Material for Different Environments

Indoor high-voltage systems: Ceramic or glass for stability and reliability.

Outdoor or polluted environments: Composite insulators for flexibility and corrosion resistance.

Heavy mechanical load: Ceramic or reinforced composite materials.

4.Applications of Busbar Insulators

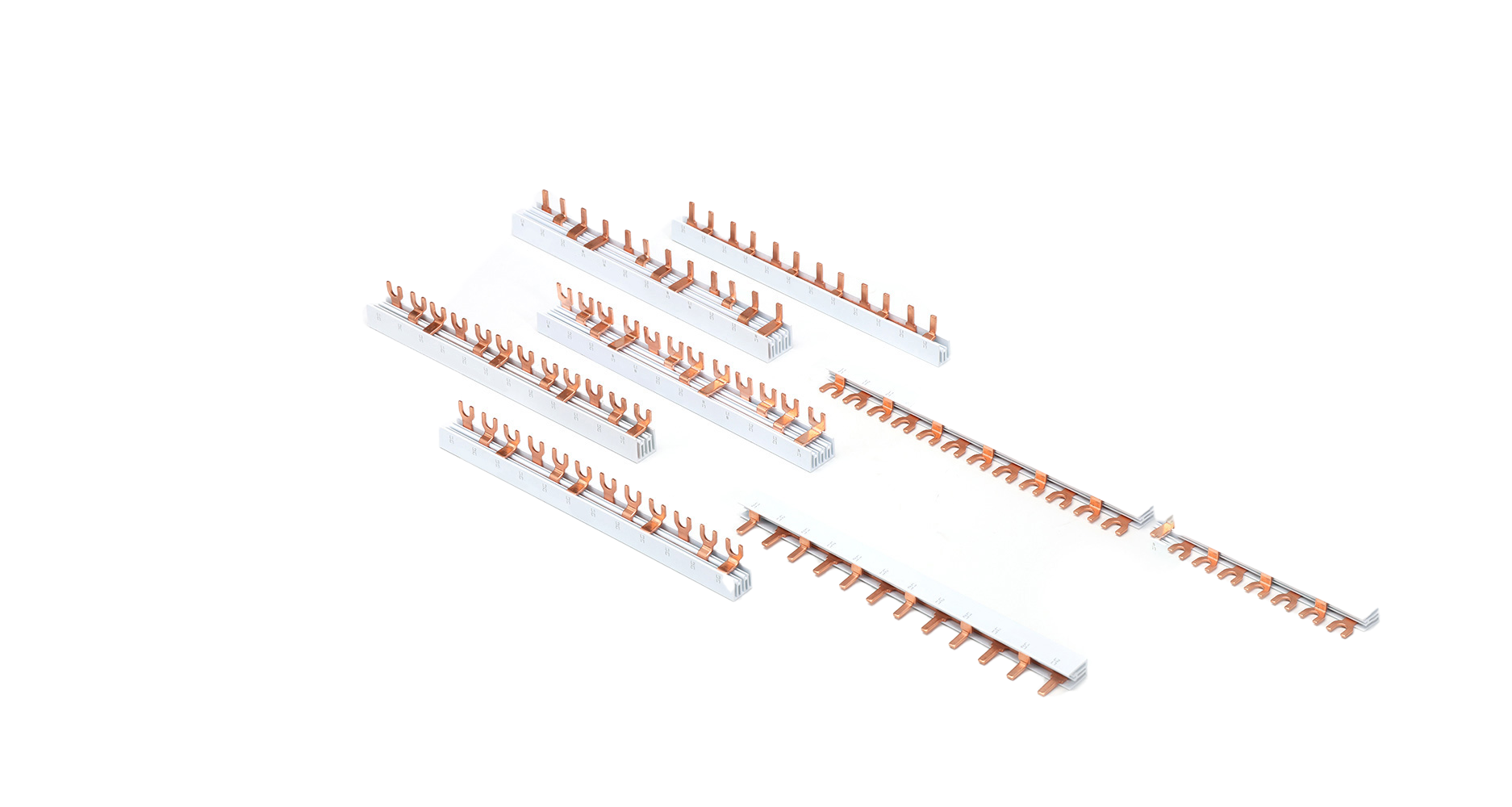

4-1 Busbar Insulator Applications

Power Plants: Support and insulate busbars in generators and transformers.

Substations: Ensure safe high-voltage transmission and distribution.

High-Voltage Distribution: Maintain reliability in transmission lines.

Industrial Automation: Support power distribution in machinery and control panels.

4-2 Special Cases: Outdoor or Harsh Environments

Composite insulators are ideal for outdoor exposure to rain, UV, or pollutants.

Suspension insulators are used where flexibility and vibration resistance are required.

5.FAQs

Q1: What is the main function of a busbar insulator?

It supports, insulates, and protects busbars to prevent faults and ensure safety.

Q2: Which busbar insulator type is best for high-voltage lines?

Suspension or composite insulators are ideal for high-voltage and outdoor lines.

Q3: How do materials affect busbar performance?

Ceramic and glass provide strong insulation and heat resistance; composite offers flexibility and corrosion resistance.

Q4: Can busbar insulators be used in industrial automation?

Yes, they are essential for safe and reliable power distribution in machinery and control panels.

Conclusion

Busbar insulators are critical for electrical safety, system efficiency, and long-term reliability. By understanding the different types, materials, and applications, engineers can choose the right insulators for indoor, outdoor, and high-voltage environments. Proper selection ensures safe power distribution, protects equipment, and reduces operational risks.