Introduction

As electric mobility continues to grow, efficient and reliable power distribution is essential. Busbars play a crucial role in connecting and distributing electricity within electric vehicles (EVs), charging stations, and renewable energy systems. Unlike traditional cables, busbar technology offers higher efficiency, reduced electrical losses, and compact designs that meet the demands of modern electric mobility.

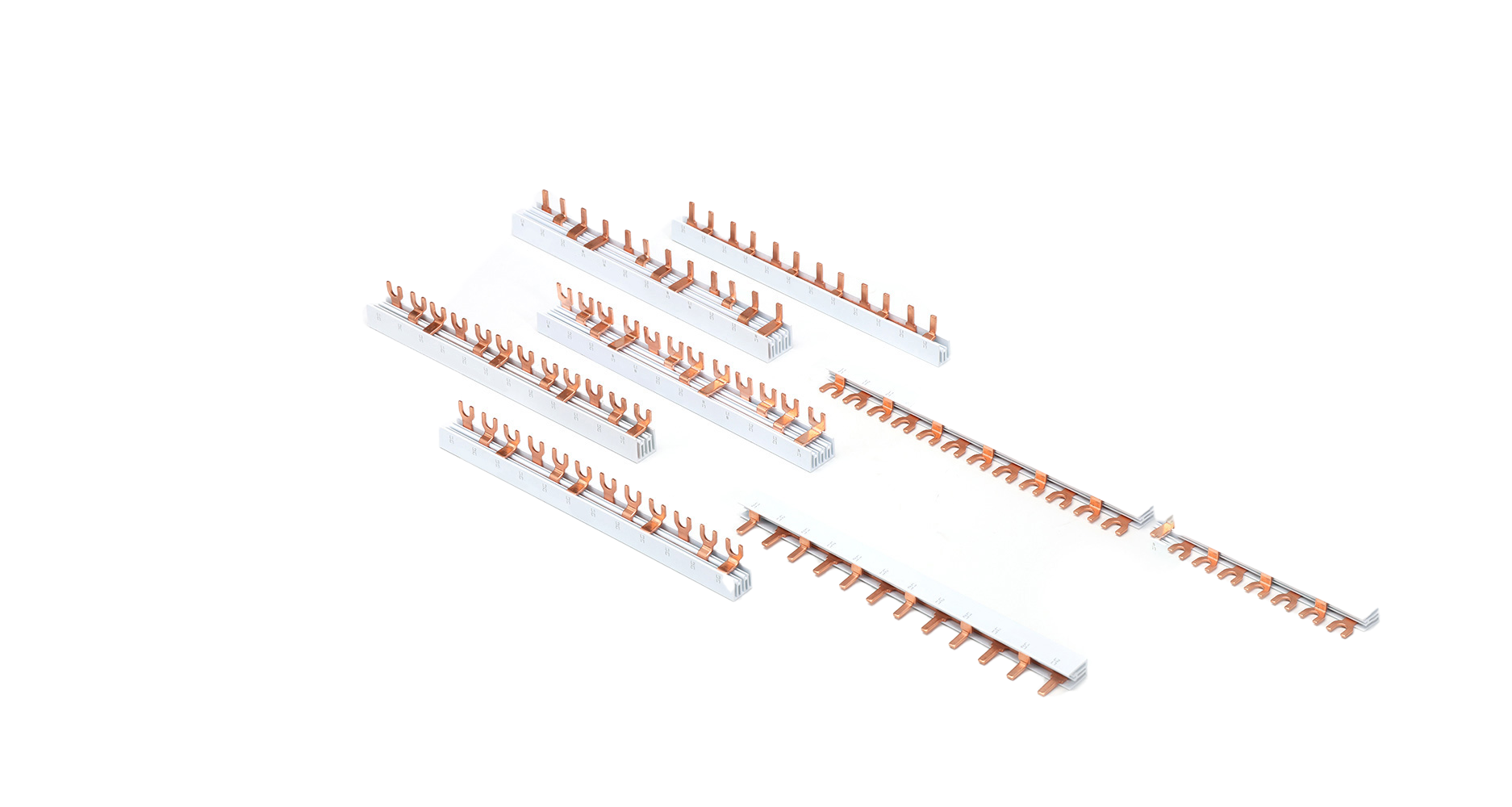

1.What Is a Busbar?

1.What Is a Busbar?

Definition of a Busbar

A busbar is a metallic conductor, usually made from copper or aluminum, designed to collect and distribute electrical power within a system.

Basic Functions and Roles

Carry high currents safely and efficiently

Distribute power to multiple circuits or components

Simplify wiring systems by reducing cable clutter

Improve heat dissipation and system safety

Comparison with Traditional Cable Connections

Compared to conventional cables, busbars provide:

Higher current capacity in a smaller space

Lower resistance and reduced power losses

Better mechanical stability under vibration and heat

Easier integration into compact EV and industrial systems

2.Busbar Technology in Electric Mobility

Features of Electric Mobility Busbar

Electric mobility busbars are engineered for high efficiency, compact design, and durability. They are often laminated or insulated to ensure safety and minimize electromagnetic interference.

High Current Carrying Capacity and Energy Efficiency Advantages

Busbars can handle hundreds of amps with minimal resistance, reducing energy losses. This is especially important in EVs where efficiency directly affects driving range.

Busbar Design in EV Battery Systems and Power Electronics

Battery packs: Busbars connect individual cells to ensure balanced energy flow.

Inverters and converters: Laminated busbars minimize stray inductance, improving performance of power electronics.

Charging modules: Busbars enable stable and fast charging by managing high current loads.

3.Types and Applications of Busbars

Busbar Applications

Busbars are widely used in:

Electric vehicles

Charging stations

Renewable energy systems

Industrial power distribution

EV Battery Connections

Busbars ensure safe, stable, and low-resistance connections between battery cells and modules.

EV Charging Systems

They allow efficient power transfer in both on-board and off-board charging systems.

Power Distribution Modules and Control Panels

Busbars integrate with power control systems, improving organization and reducing wiring complexity.

4.Busbar Materials and Specifications

Busbar Materials and Specifications: Copper, Aluminum, and Other Common Materials

Copper: High conductivity, excellent thermal performance, but heavier and more expensive.

Aluminum: Lightweight, cost-effective, with good conductivity, commonly used in EV applications.

Other materials: Coated alloys or composites for corrosion resistance and flexibility.

How Material Choice Affects Conductivity, Heat Resistance, and Corrosion Resistance

Copper offers superior conductivity and durability.

Aluminum reduces vehicle weight, improving overall efficiency.

Protective coatings enhance corrosion resistance in harsh environments.

Standard Sizes and Industry Specifications

Busbars are manufactured according to IEC, UL, and automotive standards. Typical specifications include cross-sectional area, thickness, and insulation requirements.

5.Advantages of Busbar Technology in Electric Mobility

Improved System Efficiency

Busbars reduce resistive losses and improve current flow, enhancing the performance of EV systems.

Reduced Electrical Losses

By minimizing resistance and inductance, busbars support efficient energy use, contributing to longer driving range and better battery life.

6.FAQs

Q1: Why are busbars used in electric mobility instead of cables?

Busbars offer higher efficiency, better heat management, and space-saving designs compared to cables.

Q2: Which is better for EV busbars: copper or aluminum?

Copper provides maximum conductivity, while aluminum offers a lighter, more cost-effective solution. The choice depends on system requirements.

Q3: Are laminated busbars necessary in EVs?

Yes. Laminated busbars reduce stray inductance and improve the performance of high-frequency power electronics in EVs.

Q4: What standards apply to busbar materials and specifications?

Busbars are typically designed to meet IEC, UL, and automotive industry standards for safety and reliability.

Conclusion

Busbar technology is transforming electric mobility by enabling efficient, compact, and reliable power distribution. With advanced designs, optimized materials, and wide-ranging applications, electric mobility busbars are essential to the performance of EVs, charging infrastructure, and renewable energy systems. As demand for clean transportation grows, busbars will continue to play a central role in powering the future of mobility.