Introduction

In modern electrical systems, reliability and efficiency depend heavily on the type of connection technology used. Two of the most widely adopted innovations today are the push-in connection and rail-mounted terminal blocks. When combined, they offer faster installation, higher safety, and long-term performance, making them the preferred choice in control panels, power distribution, and industrial automation.

1.What is Push-In Connection?

1.What is Push-In Connection?

1-1 Definition and Features of Push-In Connection Technology

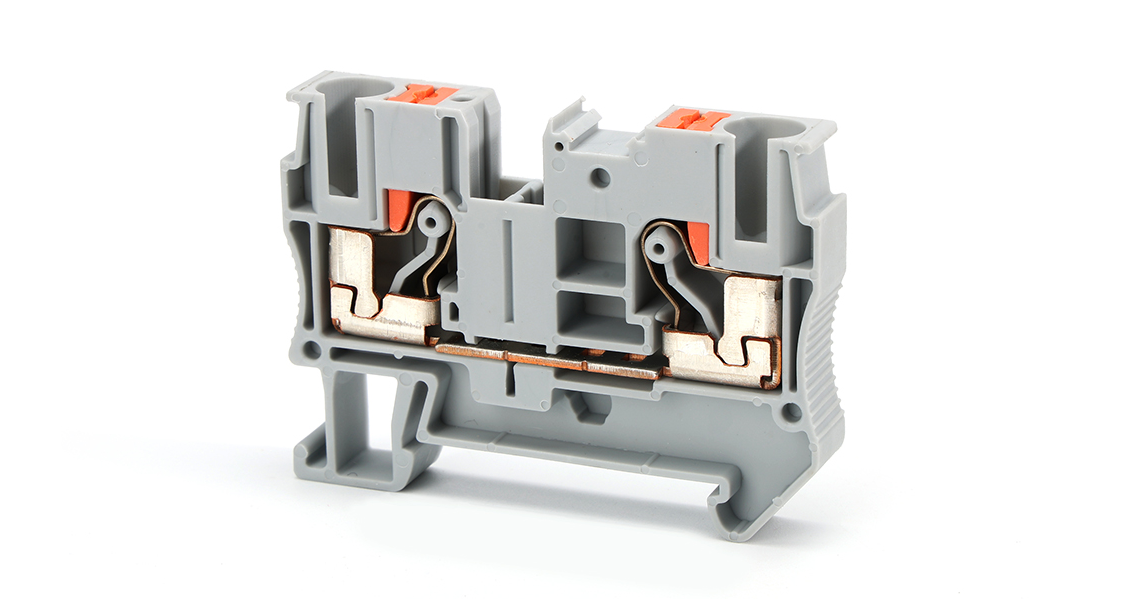

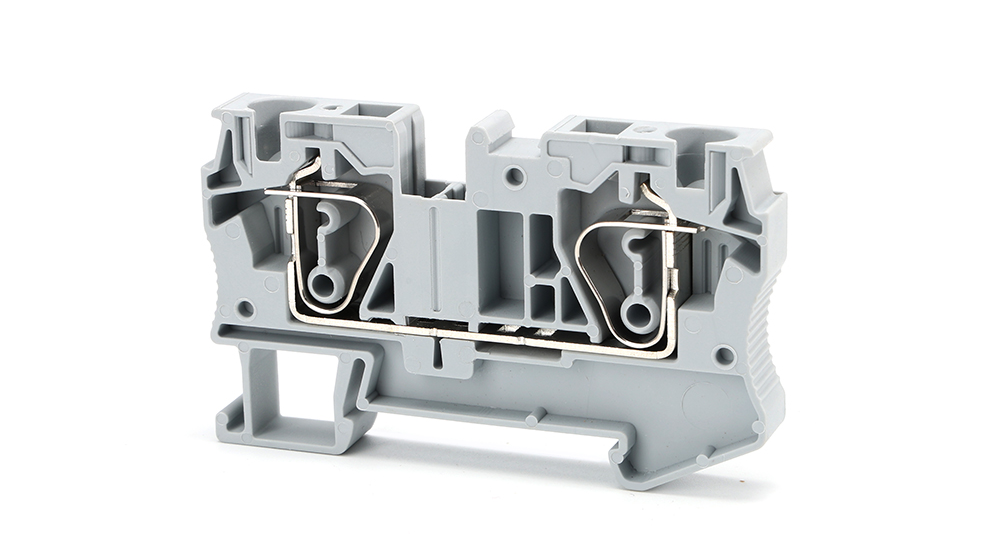

A push-in connection is a tool-free wiring method where conductors are inserted directly into a spring-loaded clamp. Unlike screw connections, which require tightening, push-in terminals create secure electrical contacts instantly. This design reduces wiring time and minimizes maintenance.

Key features include:

Tool-free conductor insertion

Strong spring pressure for reliable contact

Resistance to vibration and loosening

Compatibility with solid, stranded, and ferruled wires

1-2 How Push-In Terminal Blocks Work

Push-in terminal blocks rely on a spring cage or clamp to hold the wire in place. When the conductor is pushed into the block, the spring applies constant pressure, ensuring a tight electrical connection. This mechanism not only simplifies installation but also guarantees consistent conductivity across the system.

2.Rail-Mounted Terminal Blocks Overview

2-1 Functions and Common Applications

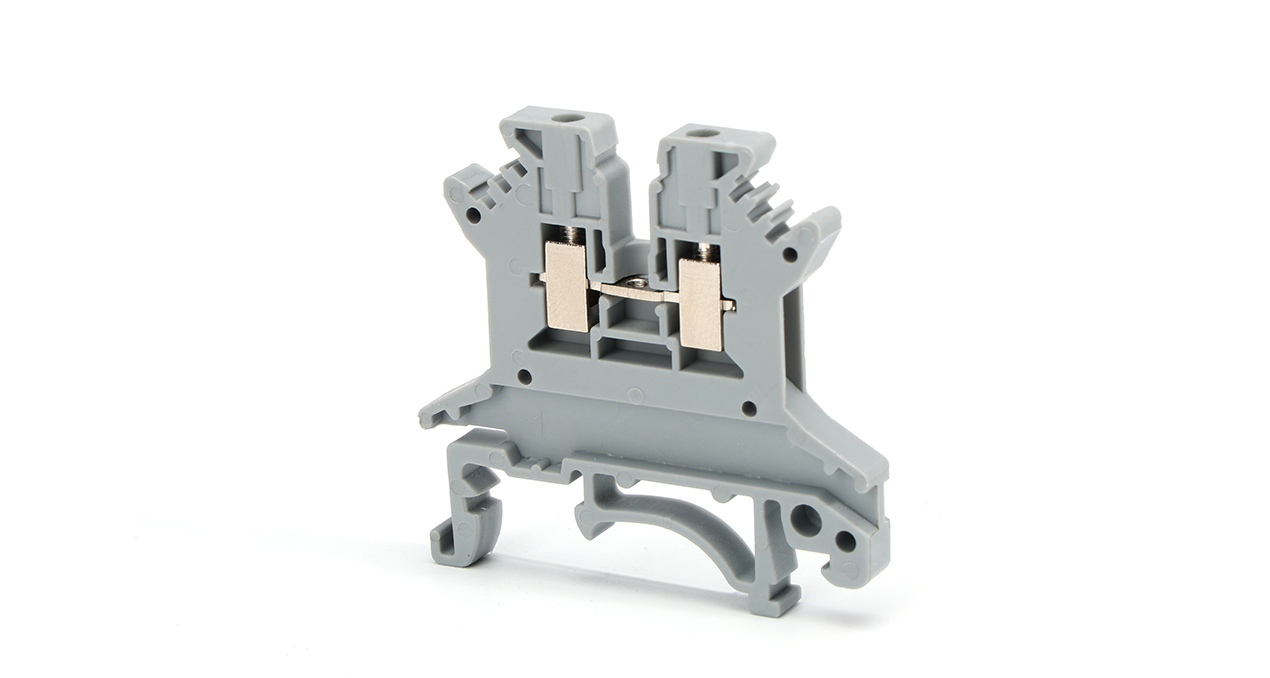

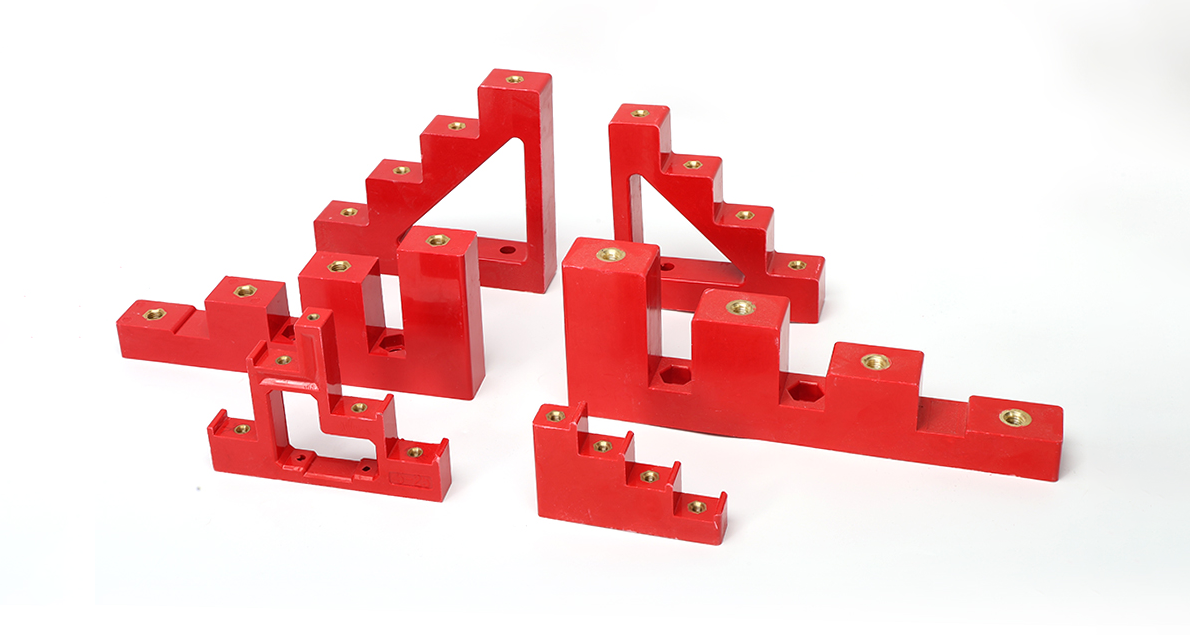

Rail-mounted terminal blocks are modular connection units designed to be mounted on DIN rails. Their purpose is to organize wiring, simplify circuit management, and improve system flexibility.

Common applications include:

Control panels

Distribution boards

Industrial machinery wiring

Automation systems

2-2 Why Rail-Mounted Design is Widely Used

The DIN rail design allows terminal blocks to be quickly snapped into place and rearranged when system upgrades are needed. This modularity reduces installation complexity and supports compact, scalable layouts, making it an industry standard for modern electrical systems.

3.How Push-In Connection Enhances Rail-Mounted Terminal Blocks

3-1 Integration Benefits

When push-in connection technology is integrated into rail-mounted terminal blocks, users benefit from faster wiring, reduced errors, and easier maintenance. Installers can connect wires without tools, saving time in both assembly and servicing.

3-2 Efficiency, Safety, and Performance Improvement

Efficiency: Quick installation lowers labor costs.

Safety: Spring tension ensures consistent contact, preventing loose connections and overheating.

Performance: High resistance to vibration makes these blocks ideal for heavy-duty applications.

4.Advantages and Comparisons

4-1 Advantages of Push-In Connection

The main advantages of push-in connection include:

Faster wiring (up to 50% quicker than screw connections)

Maintenance-free contact stability

Long-term durability in harsh conditions

Compact designs for space savings

4-2 Push-In vs Screw Connection

| Feature | Push-InConnection | ScrewConnection |

| Installation speed | Very fast, tool-free | Slower, requires tightening |

| Maintenance | Low (no retightening) | Higher (loose screws possible) |

| Vibration resistance | High | Medium, may loosen |

| Wire compatibility | Solid/stranded with ferrule | Solid/stranded wires |

4-3 Benefits for Electrical Components and Systems

Integrating push-in electrical connection benefits into terminal blocks ensures higher reliability across circuits. Components remain stable under thermal cycling and mechanical stress, extending system lifespan and minimizing downtime.

5.Applications of Push-In Terminal Blocks

5-1 Control Panels

In control panels, push-in rail-mounted terminal blocks simplify dense wiring layouts, reduce space, and speed up panel assembly.

5-2 Power Distribution Systems

For power distribution systems, push-in terminal blocks ensure safe, consistent power flow while minimizing installation errors and long-term servicing needs.

5-3 Industrial Automation and Beyond

In industrial automation, push-in terminal blocks withstand vibrations, mechanical load, and frequent operational cycles. They are also increasingly used in transportation, renewable energy, and communication infrastructure.

6.FAQs

Q1: Are push-in terminal blocks suitable for fine-stranded wires?

Yes, but ferrules are recommended to ensure reliable insertion.

Q2: Do push-in connections replace screw terminal blocks completely?

Not entirely. Screw connections are still used in some heavy-duty or specialized applications, but push-in connections are becoming dominant in most modern systems.

Q3: Are push-in terminal blocks safe for high-vibration environments?

Yes. Their spring-loaded design provides strong vibration resistance compared to screw types.

Q4: What standards do push-in terminal blocks follow?

They typically comply with IEC and UL standards, ensuring global reliability and safety.

Conclusion

The combination of push-in connection technology and rail-mounted terminal blocks represents a major advancement in terminal block connection methods. By offering speed, safety, and reliability, they address the evolving needs of modern electrical systems. Whether in control panels, power distribution, or industrial automation, push-in terminal blocks are setting new benchmarks for performance and efficiency.