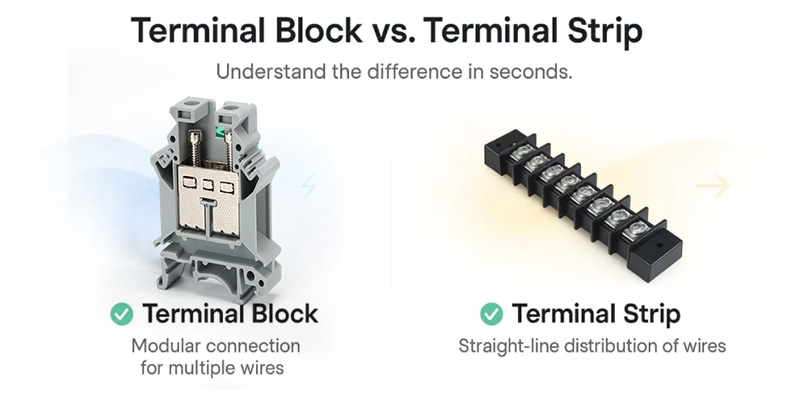

Whether you’re a seasoned procurement veteran or a newcomer to electrical components, today we’ll talk about a small gadget that can significantly improve wiring efficiency—the push-in wire connector. It’s quietly changing the way we wire, and understanding it might bring unexpected convenience and reliability to you and your projects.

What Is A Push-In Wire Connector?

Definition

The push-in wire connector is a revolutionary product that lets you say goodbye to traditional “twisted” wiring. Simply push the stripped wire straight into the hole to complete a safe and secure electrical connection.

Basic Structure

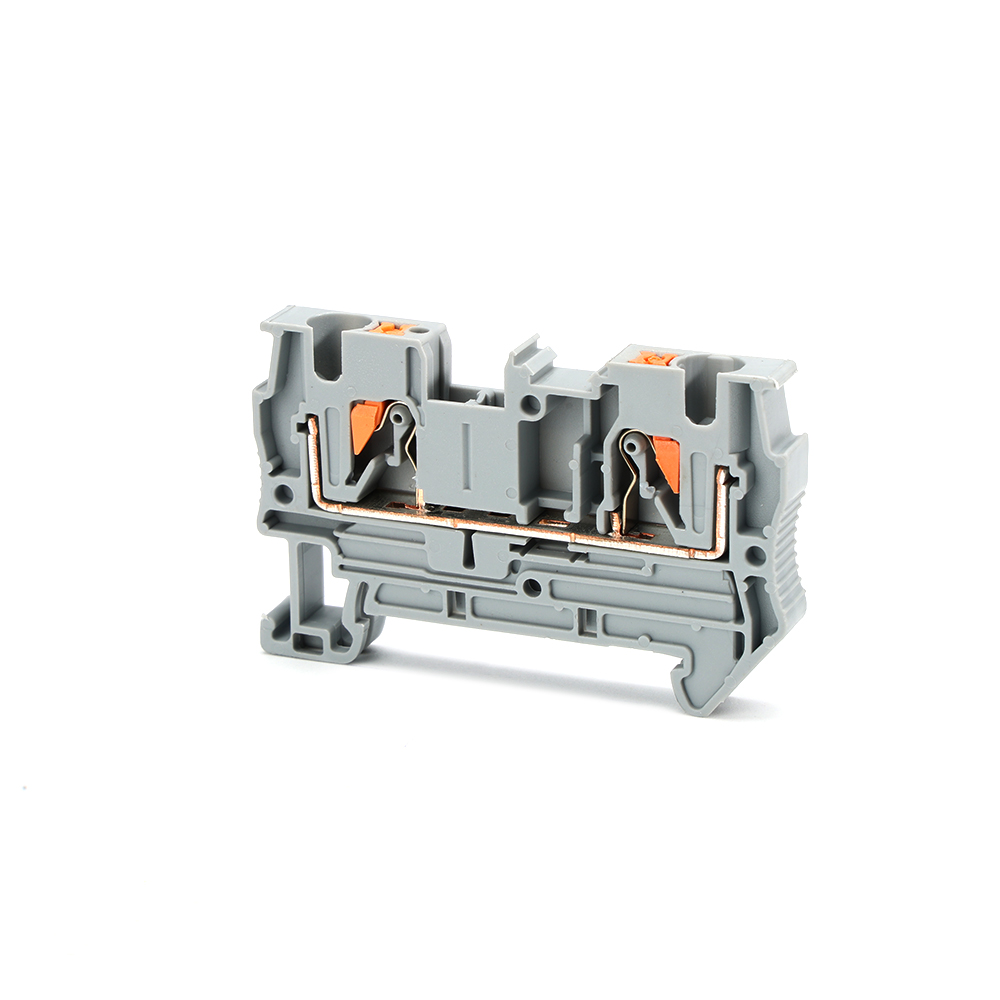

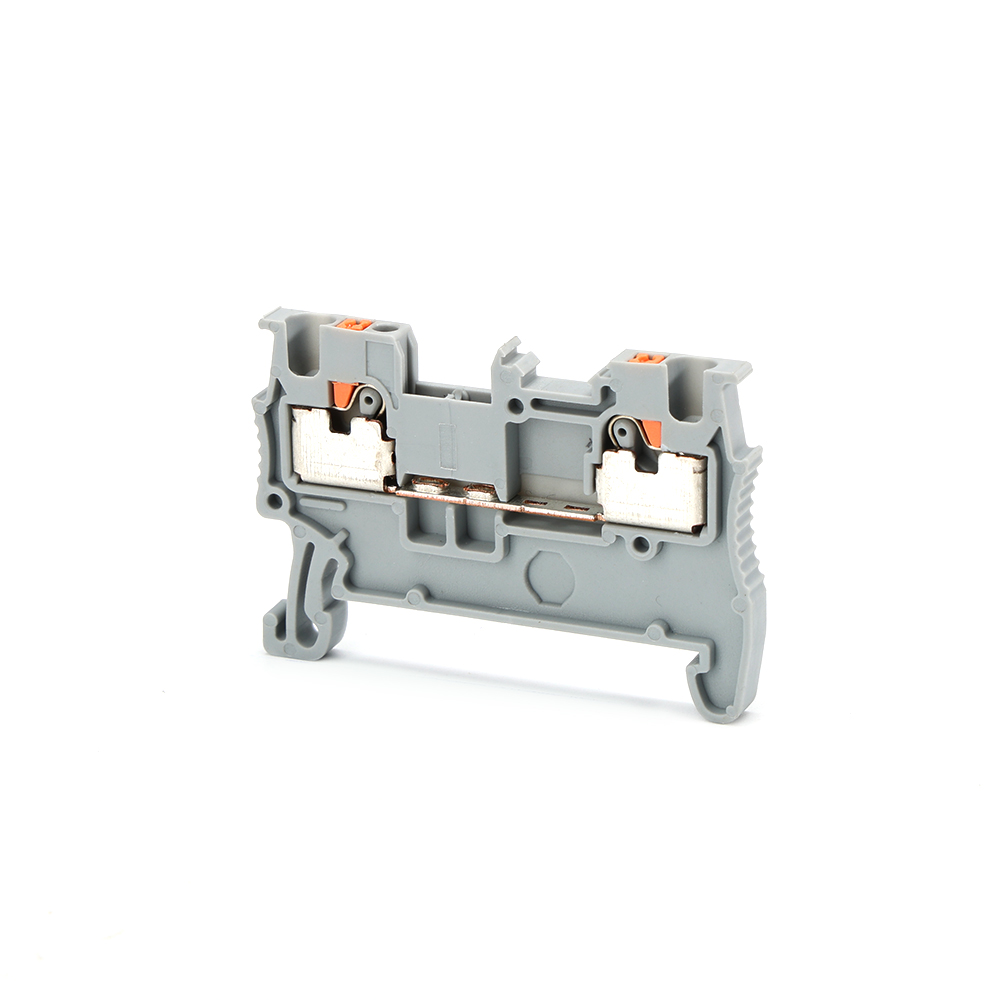

At its core is typically a transparent or semi-transparent insulating shell (allowing you to easily check if the wire is properly inserted), inside which lies the crucial spring-loaded clamping mechanism. This mechanism—usually a ring of precise, elastic metal plates—opens as you insert the wire and, relying on continuous elasticity, firmly “bites” the conductor, achieving reliable electrical contact and mechanical fixation.

Working Principle

Imagine the push-button mechanism of a ballpoint pen; it’s somewhat similar, but more sophisticated. Its core principle is “constant spring pressure connection.” When you push the wire in, the internal V-shaped or wedge-shaped spring expands outwards, then uses its strong rebound force to firmly press the wire against the conductive strip. This design ensures low contact resistance, vibration resistance, and long-term stability.

Main Types

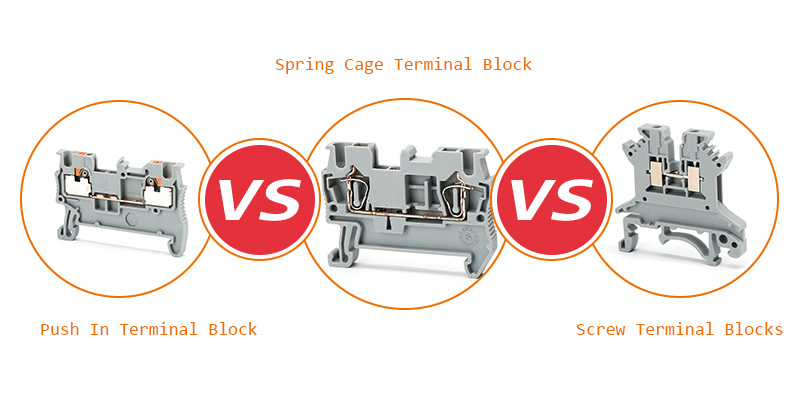

To adapt to different scenarios, it has evolved into various forms:

Operation Method

The most classic is the push-in type, requiring no tools; there’s also the lever-reset type, which comes with a small wrench. Pressing down the wrench opens the hole, inserting the wire, and releasing it locks it in place, making disassembly particularly convenient.

Wiring Direction

There are straight-through types (wires are inserted from both ends), bridging types (for parallel wiring), and composite types with pins.

Main Uses

From standard household lighting circuit connections to signal line paralleling in industrial control cabinets, there are corresponding product series. For example, Beiye Electric offers a full range of Electrical Push Connectors, from compact 2-port to multi-functional 8-port models, covering most application scenarios.

Are Push-In Wire Connectors Any Good?

Frankly, if you’re buying in bulk or managing large projects, its advantages are very clear. Traditional wire cap tightening takes time and skill, and you have to worry about inconsistent tightness due to varying skill levels among experienced installers. Push-in connectors, on the other hand, simplify the wiring process to a single “push” motion, resulting in extremely high consistency.

I once heard of a case where a commercial complex installed thousands of downlights. After the contractor switched to push-in connectors, the estimated wiring time was reduced by nearly 30%, and the failure rate for loose wiring during subsequent inspections was zero. This isn’t just about speed; it’s about improved quality control. Of course, it also has limitations, such as strict requirements on wire diameter and a higher initial investment than traditional wire caps—but considering labor costs, reliability, and consistency, its overall value is often superior.

How To Open Push-In Wire Connectors?

That’s a good question! Incorrect operation can damage the internal spring contacts. Remember, never pull the wire directly or forcefully.

For the most common leverless push-type wires, the correct way to open them is to gently rotate the wire clockwise or counterclockwise while smoothly pulling it out in the opposite direction of insertion. The rotation helps release the clamping force of the spring contacts. If it’s a model with a reset lever, it’s much simpler—just press the lever all the way down, and the wire can be easily removed without damage. Developing good habits will save you a lot of trouble when debugging or modifying the wire.

Selection Of Electrical Push Connectors

Faced with a dazzling array of products on the market, how do you make informed choices for your project? Here are a few key points:

Certifications and Compliance: This is the bottom line. Always choose products that clearly display relevant safety certifications for Push-In Wire Connectors (such as UL, CE, VDE, etc.). This is not only a guarantee of quality but also a legal and insurance requirement. Beiye Electric’s products have all passed rigorous international certifications, ensuring worry-free procurement.

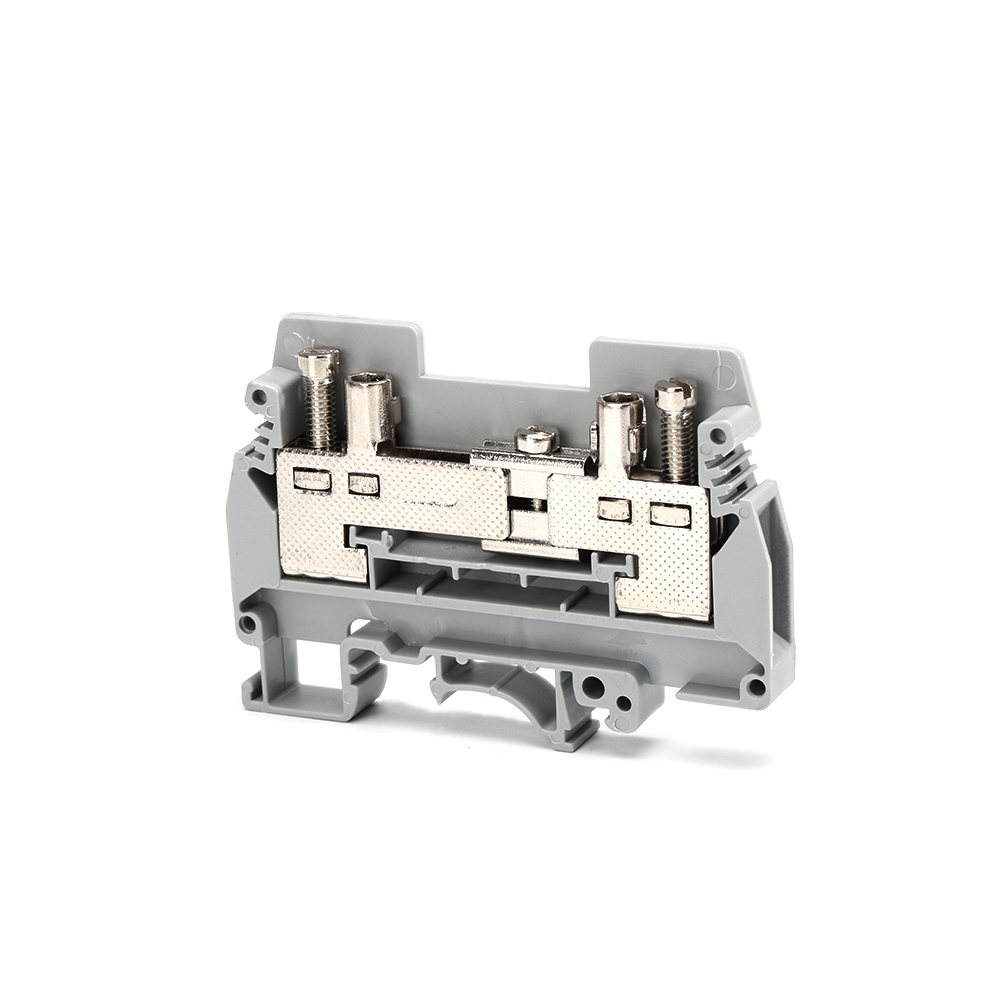

Matching Wire Gauge Range: This is the most important technical parameter. Each connector has clearly defined applicable wire gauges (e.g., 0.5-2.5 mm²). Never use a connector with a wire gauge that is too small or too large for your needs. Ensure that the wire gauge you are connecting falls entirely within the product’s specified range; otherwise, contact reliability will be affected.

Materials and Workmanship: Is the shell flame-retardant and heat-resistant? Are the internal metal components made of phosphor bronze or other high-quality alloys? Is the manufacturing process precise? A good connector feels solid in your hand. A transparent shell design is a plus, facilitating visual inspection.

Choose the type and number of ports according to your needs: Select the appropriate number of ports and structure based on your wiring requirements (parallel, split, or extension). Before purchasing, it’s advisable to obtain some samples for field testing; this is the best way to verify compatibility and feel.

FAQ

Are Push-In Wire Connectors Legal?

As long as the product is certified by an authoritative organization (such as UL, IEC, etc.) and installed strictly according to the manufacturer’s instructions (including using the correct wire gauge, full insertion, etc.), it is completely legal and recognized in most electrical installation codes worldwide.

In Which Scenarios Are Push In Connectors Suitable For Use?

It is ideal for applications requiring quick, clean, and reliable wiring. For example: residential switch and socket wiring, lighting fixture installation, low-voltage control wiring in control cabinets, and any compact equipment where space-saving is required. However, it may not be the best choice for temporary wiring requiring frequent plugging and unplugging for adjustments.

Is It Suitable For Multi Stock Lines Or Single Stock Lines?

Generally, standard push-in connectors are better suited for handling single-strand hard wires. For multi-strand soft wires, some specific models (usually requiring more precise wire gauge or pre-installed pin sleeves) can handle them, but always consult the product specification sheet to confirm. Beiye Electric’s product manual provides clear guidance on this.

How To Determine The Quality Of Connectors?

Look for certification marks, material specifications, and workmanship details (such as burrs and transparency), and test it yourself. A good connector will have a clear “click” or a slight resistance when inserted, and the clamping force will be even and firm. Brand reputation and the completeness of the technical documentation provided by the manufacturer are also important factors.

What Specification (Wire Diameter Range) Of Connector Should I Choose?

This depends entirely on the cross-sectional area (wire diameter) of the wire you need to connect. Measure or confirm your wire size (e.g., 1.5mm² or 2.5mm²), and then choose a model that fully covers that wire diameter. For example, a model labeled “1.0-2.5 mm²” can be safely used with 1.5mm² wires.

Conclusion

Push-in wire connectors are more than just simple wiring tools; they represent a more efficient, consistent, and reliable electrical connection solution. For buyers who prioritize project quality and efficiency, choosing the right brand and model means embedding stability into the project from the ground up.

Inject efficient and reliable assurance into your next project.

When you’re looking for answers to the efficiency and stability of your electrical connections, Westlec is always there. We understand that a high-quality connector is crucial to the smooth “breathing” of the entire circuit. Westlec push-in connectors, with their precision-engineered materials, rigorous certifications, and user-friendly design, simplify complex wiring with a simple “push.”

We provide not only products, but solutions. If you are evaluating new electrical accessory suppliers or have questions about selection for specific applications, please contact us. Our technical team is ready to provide samples, detailed catalogs, and professional technical support to help you find the perfect match for your project needs.

Making connections simple and superior. Choose Westlec, connect to the future.