Whether you’re assembling a new control cabinet or looking for an upgrade for older equipment, DIN rails and rail-mounted terminal blocks are the core building blocks for creating a safe, clean, and efficient electrical connection system—this guide will help you quickly grasp all the key points from selection to maintenance.

What Is Din Rail

Imagine you need to neatly secure dozens, even hundreds, of wire connections inside an electrical control box. A haphazard, tangled mess? Clearly unprofessional and unsafe.

This is where DIN rails come in. They are standardized metal rails with a cross-section shaped like a hat or a “G,” allowing for easy mounting on back panels. Their purpose is to provide a standardized, plug-and-play mounting framework for various modular electrical components—such as circuit breakers, relays, and, of course, our focus today, DIN rail terminal blocks.

What Is Din Rail Mount Terminal Block

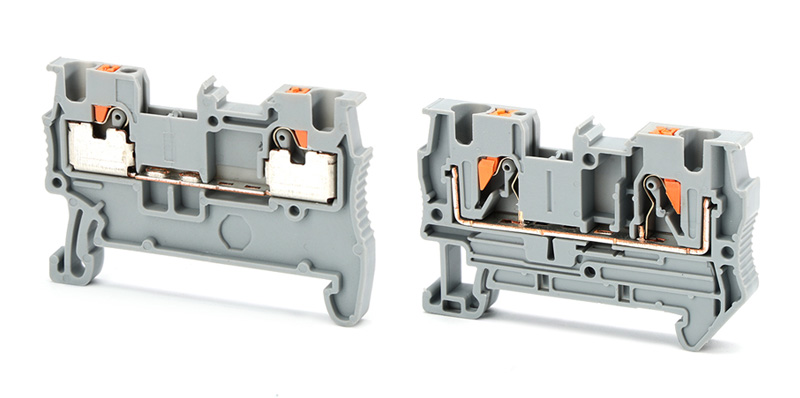

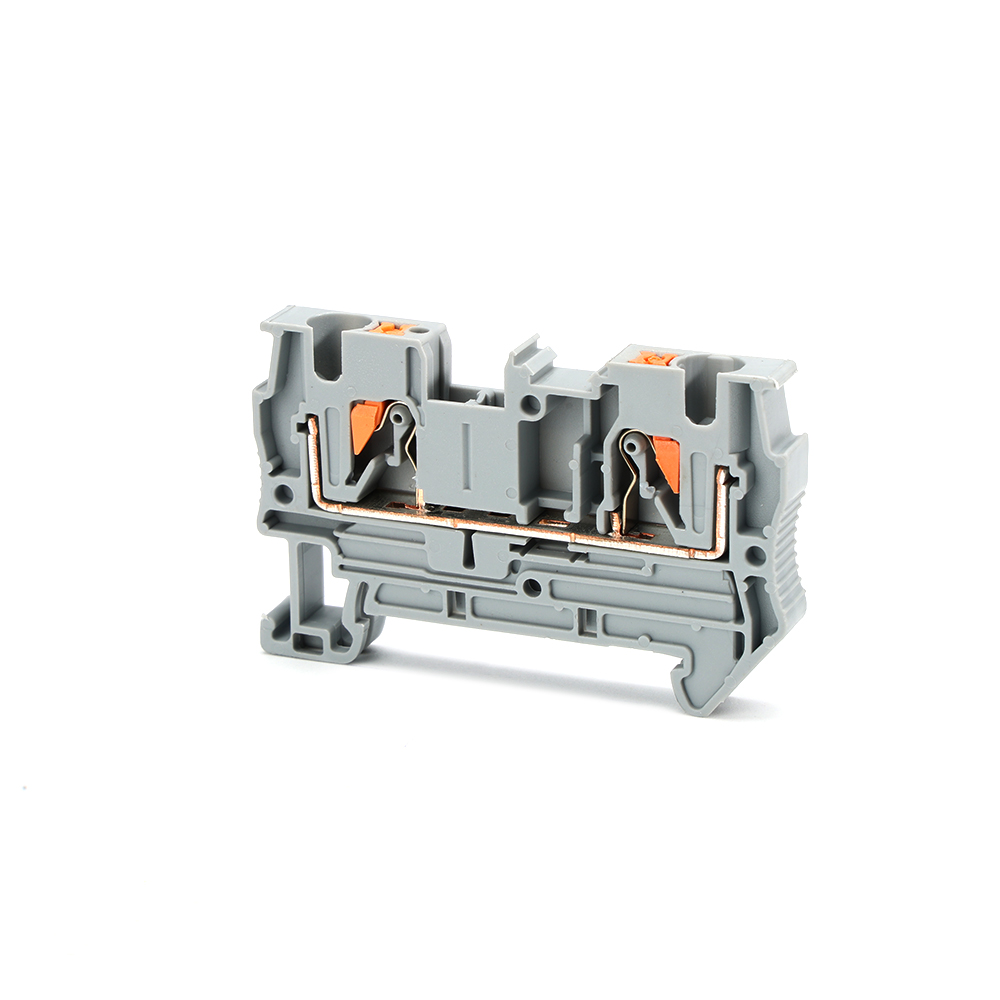

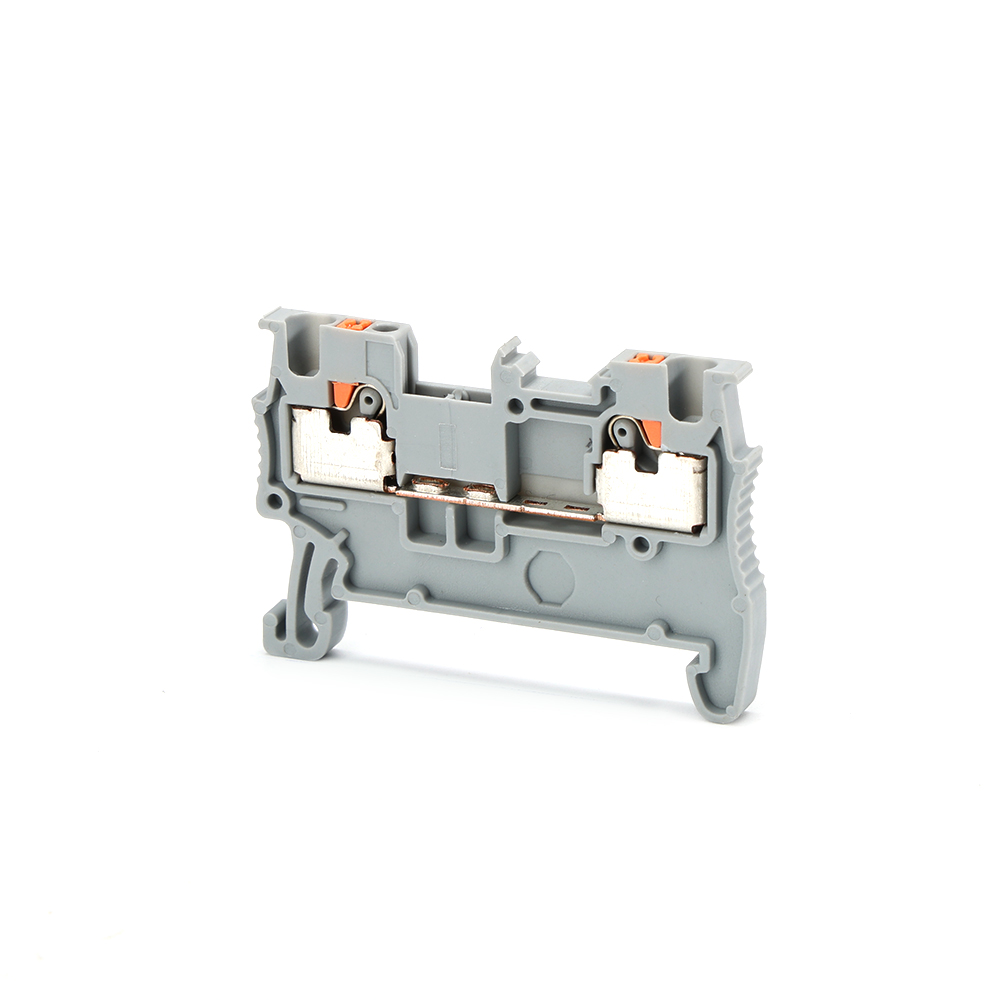

DIN rail terminal blocks are terminal blocks that snap onto DIN rails like building blocks. They completely replace traditional terminal blocks that require drilling holes one by one, significantly improving your installation efficiency.

For example, Westlec’s TB series terminal blocks simply require aligning the back clips with the rail and pressing them down; you’ll hear a crisp “click” to indicate they’re in place. Removal is equally easy; simply pry up the clips with a screwdriver—it’s incredibly flexible.

Features Of Rail Mounted Terminal Blocks

As a savvy buyer, you’re certainly interested in “what makes it so good?” Besides the modular installation mentioned earlier, it boasts several features that engineers will adore:

Unparalleled flexibility: Need to add a circuit? Simply add another terminal block to the empty space on the rail. This scalability is a godsend for future upgrades.

Ultimate neatness and order: All terminals are neatly arranged with clear wire markings, significantly reducing wiring errors and making troubleshooting much easier.

A real-world example is a factory that, after upgrading its production line and adopting rail-mounted terminals, reduced control cabinet wiring time by 30% and achieved 100% consistency between the drawings and the actual components.

Excellent safety and reliability: High-quality products, such as those offered by Westlec, use highly flame-retardant and high-temperature resistant materials (such as PC and PA66) and are designed with finger-touch protection to prevent accidental electric shock. The torque of the fastening screws is stable, ensuring they won’t loosen even under long-term vibration.

Rich functional variations: It’s not just about connecting two wires. You can choose from various terminal blocks with fuse holders, signal surge protectors, diodes, bridging plates, or even PCB connectors to achieve different circuit functions.

Install Terminal Block For Din Rail

Installation itself is simple, but “the devil is in the details.” Proper installation ensures decades of worry-free operation.

1. Prepare the rails: First, securely install the appropriate length and material of the DIN rails (35mm standard is common) onto the back plate with screws. Ensure they are straight, otherwise it will affect the stability of the terminal blocks.

2. Install the terminals: Align the spring clips on the back of the terminal blocks with the upper edge of the rails and press down until you hear a locking sound. You can arrange all the necessary terminals at once for more efficiency.

3. Wiring: This is the most crucial step! My strong recommendation is to use a suitable screwdriver and follow the manufacturer’s recommended torque. Over-tightening will damage the wire core or threads, while under-tightening will result in excessive contact resistance and overheating. Neatly trim the wire ends, insert them into the terminal holes, and then tighten evenly. Don’t forget to clearly label or attach the wire numbers!

4. Leave space: When installing multiple terminal blocks, always leave a small gap between them. This helps with heat dissipation and makes it easier to handle with fingers or tools. Don’t pack them too full, otherwise it will be very troublesome to replace one of them individually in the future.

Daily Maintenance And Troubleshooting

Even the best products require proper maintenance. Regular inspections (e.g., annually) are a good habit.

Routine maintenance: Primarily visual inspection. Check for discoloration of terminals due to overheating (usually yellowed or blackened), smell for any unusual burnt plastic odor, and listen for any hissing sounds caused by poor contact. Keeping the cabinet clean and dry is also important.

Common Wiring Problems And Avoidance Methods

Problem: Loose wiring causing overheating.

Prevention: Use a torque screwdriver and regularly check for tightness, especially in vibrating environments.

Problem: Burrs on wire ends causing short circuits.

Prevention: Always use professional cable stripping tools to ensure the bare wire is of the correct length and that there are no unraveling copper strands.

Problem: Incorrect selection leading to burnout.

Prevention: This is crucial! Voltage and current specifications must have a margin of safety. For inductive loads (such as motors), the current rating should be 1.5-2 times higher than the rated value. High ambient temperatures will reduce current carrying capacity, requiring derating.

FAQ

What should be considered when choosing DIN rails of different materials?

galvanized steel is the most commonly used due to its high strength and economy; aluminum alloy is lightweight and corrosion-resistant, suitable for marine equipment or weight-sensitive applications; stainless steel is used in environments requiring extremely high corrosion resistance (e.g., chemical plants, food processing plants, and humid areas). When purchasing, a balance between cost and actual environmental requirements is necessary.

What issues should be considered when replacing wiring terminals on old equipment?

Safety first! First, disconnect and test the power. Then, carefully record the original wiring sequence, migrate each cable one by one, and mark the new wiring. Also, check the insulation of the old cables for brittleness and replace them if necessary. This is a good opportunity to improve equipment reliability.

The relationship between insulation class and environment for rail-mounted terminal blocks

Insulation class is like a “temperature protection charm” for terminals. It tells you how high the long-term operating temperature the terminal body material can withstand (such as 105°C for Class I). However, in actual use, environmental factors—especially high temperature, humidity, dust and chemical corrosion—can work together to “weaken” this protection, forcing you to choose products with higher insulation class or stronger protection (such as IP rating) for harsh environments.

How should voltage specifications of DIN rail terminals be matched?

The rated voltage must be higher than the actual system voltage. In a 380V AC system, terminals with a rated voltage of at least 500V or 600V should be selected. For signal or low-voltage circuits (e.g., 24V DC), voltage specifications are easier to meet, but more attention should be paid to interference immunity and shielding.

How can we avoid operational inconvenience caused by insufficient spacing when installing multiple terminal blocks side by side?

Plan ahead! When laying out the terminals, reserve at least one terminal width’s width of space between them, or directly choose a “comb-shaped” baffle with operating clearance. Imagine a future scenario where you need to reach in to tighten screws; make room for that now.

Conclusion

In the world of electrical connections, details determine success or failure. A seemingly insignificant terminal block carries the stable transmission of signals and energy, affecting the safety and efficiency of the entire system. Choosing DIN rail terminal blocks and DIN rails means choosing standardization, reliability, and ease of future maintenance.

Stop worrying about messy cables and unreliable connections. Whether for standard applications or special needs, Westlec is a reliable choice. Contact our technical and sales teams today for a customized product catalog, technical specifications, and a competitive quote.