Industrial users deal with various terminals every day, and choosing the right one can indeed make all the difference. Below is a systematic overview of electrical terminal types, covering their types, key differences, applicable scenarios, and common pitfalls, aiming to improve your selection and application efficiency.

Types of electrical wiring terminals

Classification by Structure

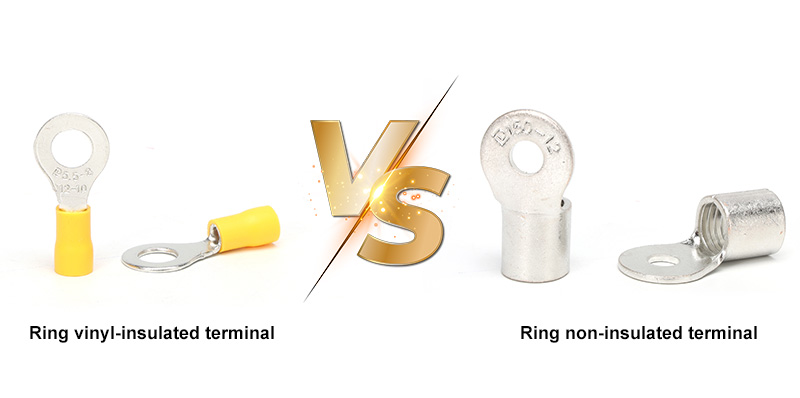

Screw terminals

Classic and widely used, tighten the wire by tightening the screw. Suitable for most industrial scenarios, especially for thick wires or high current applications. However, screw terminals should be noted that uneven force during manual tightening may result in poor contact.

Spring terminals

Spring terminals using spring pressure to fix wires, fast wiring, and good vibration resistance. For example, in conveyor belts or motor control boxes, spring terminals can effectively cope with continuous vibrations. However, they have strict requirements for the range of wire diameters.

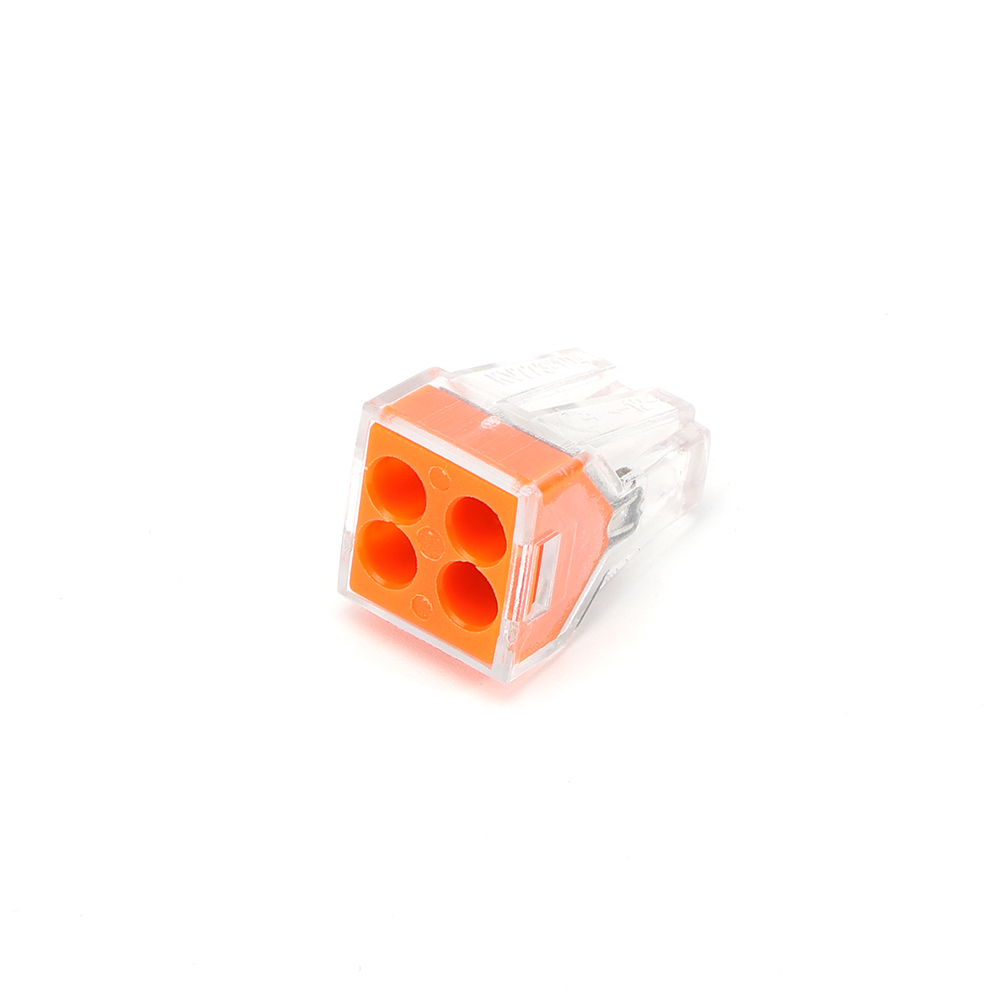

Push in terminals

Simply insert the stripped wire into the hole to complete the connection, saving a lot of installation time. But many people are worried – ‘Will they loosen after prolonged use?’ We will discuss it in detail in the FAQ later.

Barrier terminals

Adopting a separate structure to prevent accidental contact between adjacent wires. Commonly used in power distribution or high voltage applications, Westlec’s barrier terminal series incorporates fire-resistant materials to enhance safety.

Classification by Function

Grounding Terminal

Usually marked in green or yellow-green, dedicated to safe grounding. It is essential to ground the metal casing of the equipment – I have seen cases where loose grounding terminals caused electrical shock to the equipment, so it is necessary to regularly check it!

Fuse terminals

Built-in fuse holder, providing overcurrent protection. Very suitable for distributed control modules that require integrated protection.

Disconnecting terminals

By unplugging the plug, the circuit can be disconnected for convenient and safe maintenance. Especially practical in testing stations that require frequent debugging.

Multi-layer terminals

Allow for multiple connections within a limited space and optimize the layout of the control cabinet. Westlec’s multi-layer terminals use transparent shields, making the circuit status clear at a glance.

Classification by application field

PCB terminals

Directly solder onto the circuit board and connect the external wires of the board. When selecting, attention should be paid to matching the type of solder joint with the thickness of the board.

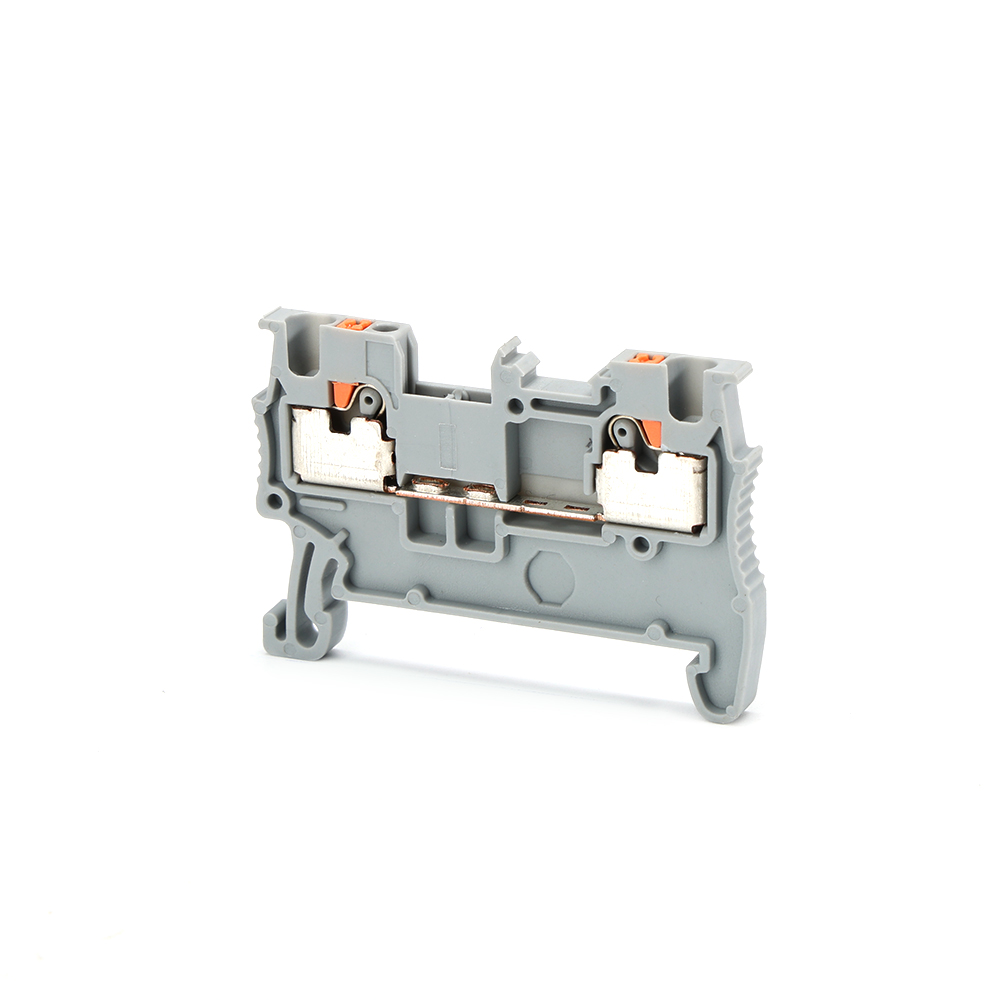

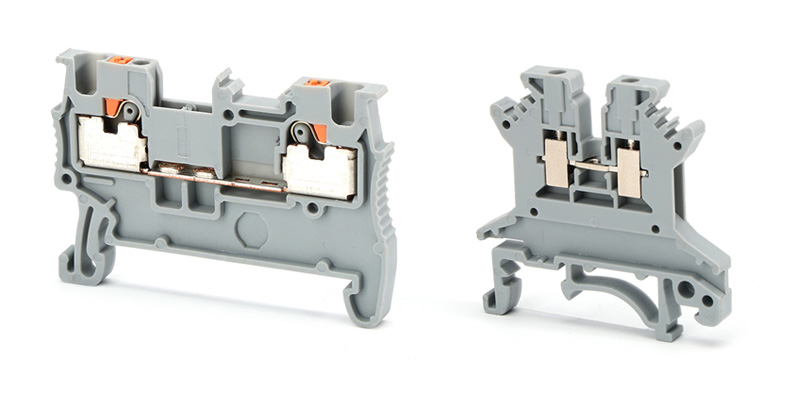

Terminals For Din Rail

It can be quickly mounted on standard DIN rails, and the modular design makes expansion and reassembly flexible. This is the “skeleton” of modern industrial control cabinets. Westlec’s DIN rail terminal series offers multiple colors and identification options to simplify management.

On-site wiring terminals

Used for on-site instrument or sensor access, usually with a protective casing. For example, in humid environments, using IP67-rated terminals can avoid faults caused by corrosion.

Special type terminals

Thermocouple terminals

Specially designed for thermocouple signals, using metal sheets of the same material to reduce thermoelectric potential errors. In kiln temperature monitoring, using ordinary terminals may cause reading drift.

Network/Signal Terminals

Used for communication lines such as Ethernet and Profibus, with shielded interfaces. The impedance matching and shielding treatment inside the terminal are crucial for high-speed signal transmission.

FAQ

Should You Tin Wires For Screw Terminals?

Not recommended! Tin-plated wires may creep under screw pressure, leading to loose connections. Directly use bare copper wire to ensure tight contact between the screw and the copper wire. If you are concerned about oxidation, you can choose coated wires or apply antioxidants.

Do Push-In Connectors Weaken Over Time?

Spring-type push-in terminals usually have a longer lifespan, but if frequently plugged in or overloaded, metal fatigue may cause a pressure drop. It is recommended to conduct regular inspections in critical circuits or choose products like Westlec that provide high-cycle certification.

What Is The Difference Between A Terminal And A Terminal Block?

Terminals usually refer to a single connection point, while terminal blocks are multiple terminals integrated into a module. For example, a terminal block is often installed on a DIN rail, containing multiple independent circuit connection points.

Conclusion

When selecting electrical terminals, it is necessary to comprehensively consider current, voltage, environmental vibration, installation efficiency, and maintenance requirements. Both traditional screw terminals and convenient push-in designs have their best application scenarios. Reliable products are equally important as proper installation – after all, even the best design relies on the stability of every connection point.

Westlec offers a full range of industrial-grade electrical terminals, from high-performance DIN rail terminals to corrosion-resistant on-site wiring solutions, all of which have passed rigorous environmental testing.