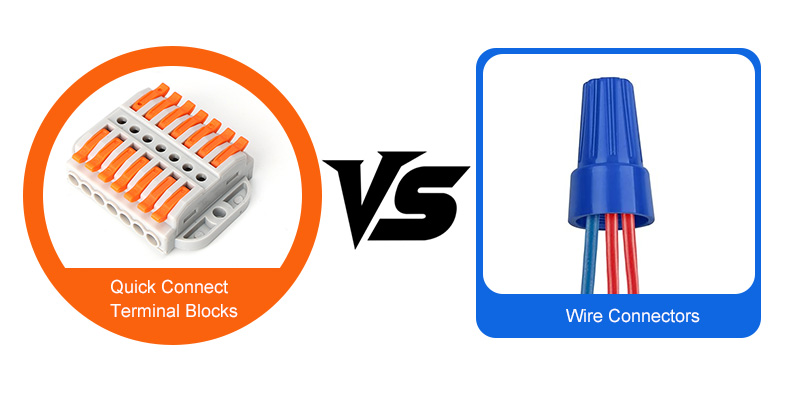

Choosing the correct type of DIN rail terminal block is not a matter of chance, but rather a systematic decision-making process based on specific application requirements.

To help you make a clear and efficient choice, we have distilled five core questions. By answering these questions, you will be able to quickly identify the most suitable type of DIN rail terminal block for your project.

5 Questions Before Choosing Din Rail Terminal Blocks Type

What Are The Current And Voltage?

Current and voltage are the primary technical parameters for selecting terminal blocks. The terminals must be able to safely and continuously carry the maximum current in the circuit and have a corresponding rated voltage level.

For high-current (e.g., above 50A) or high-voltage applications, it is essential to select DIN rail terminal blocks with sufficient safety margins, made of high-specification materials (such as copper alloy), and featuring a more robust structure. Neglecting this can lead to terminal overheating, insulation damage, and serious safety hazards.

Is It A Power Supply, Signal, Or Control Circuit?

The nature of the application circuit directly determines the requirements for the terminals.

Power circuits: These typically involve high currents, requiring terminals with low contact resistance, high current carrying capacity, and excellent stability. Screw terminals are very common in these applications due to their high clamping force and reliable contact.

Signal or control circuits: These typically involve low currents (milliamperes), but may have high requirements for corrosion resistance and interference immunity. In this case, spring terminals or precision terminals with gold-plated contacts can provide more stable and vibration-resistant signal transmission.

How Compact Is The Installation Space?

Space inside control cabinets is always at a premium. The width of the terminal blocks (the spacing between each pole), their height, and whether they allow for safe operation in a densely packed arrangement are all crucial factors to consider. Modern DIN rail terminal blocks are increasingly compact, especially spring-loaded terminals, which, because they don’t require side-access for tightening tools, typically offer more connection points per unit length, making them ideal for high-density wiring.

Does It Require Frequent Modification Or Maintenance?

If the wiring needs frequent modifications, debugging, or testing, the convenience and speed of the wiring operation become extremely important.

Screw terminals: require a screwdriver, making the operation relatively slow, but the connection is intuitive and reliable.

Spring terminals: connections can be completed using a push-in tool or by directly inserting the wires, resulting in extremely fast connections and significantly reducing installation and maintenance time, especially suitable for applications requiring frequent modifications.

What About The Environment (Vibration, Humidity, Dust)?

The working environment is a key factor affecting long-term reliability. Screw terminals may be at risk of loosening under prolonged and severe vibration. Spring terminals, on the other hand, maintain contact using constant spring pressure and perform better in high-vibration environments. For humid, dusty, or corrosive environments, it is necessary to select terminals with the appropriate protection rating (IP rating) or use accessories such as sealing covers.

How To Choose

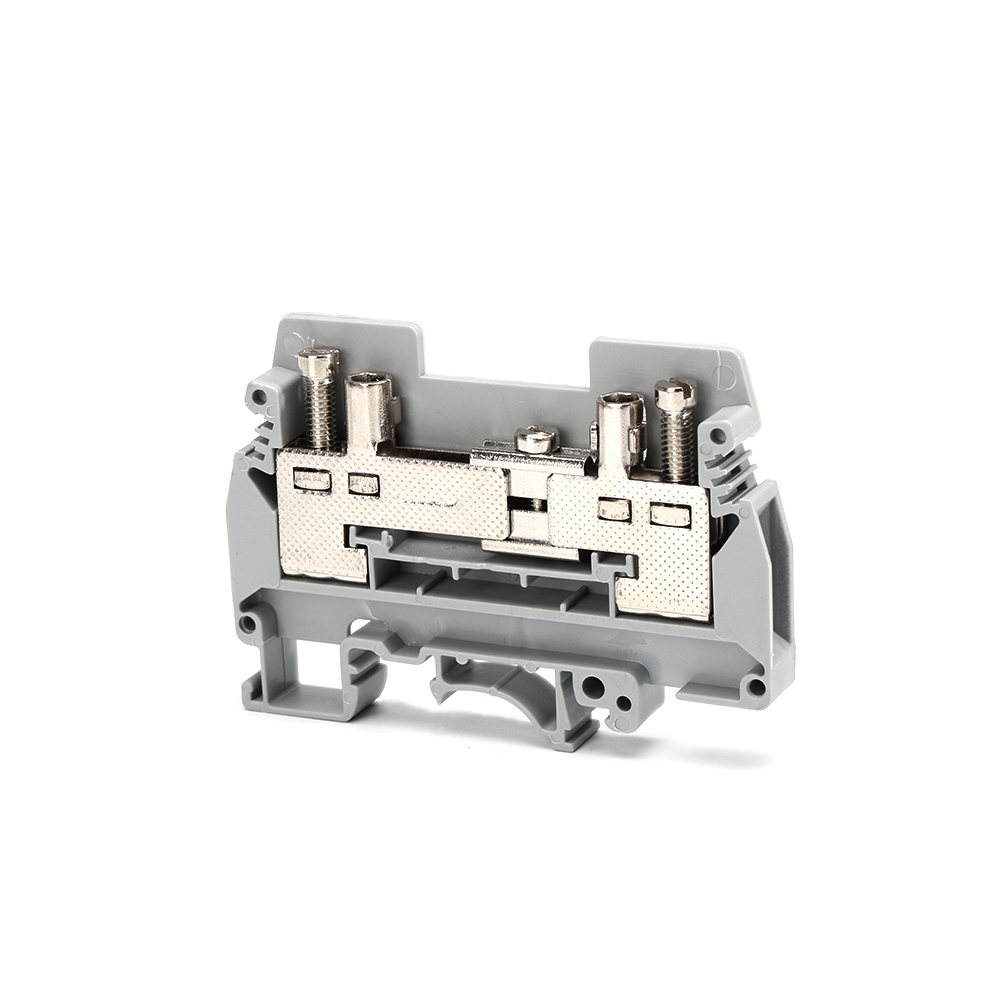

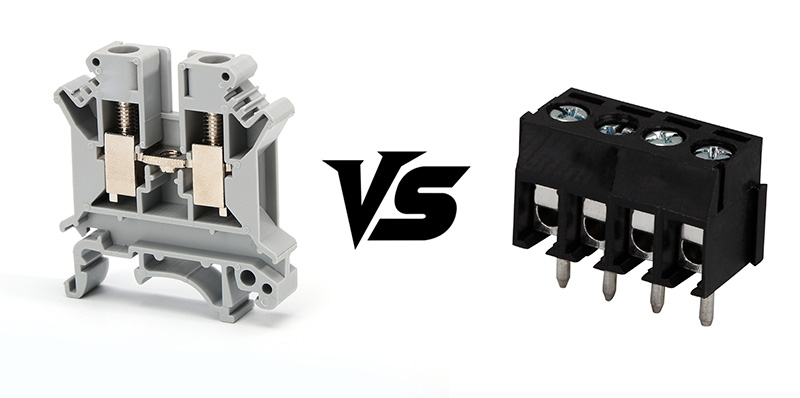

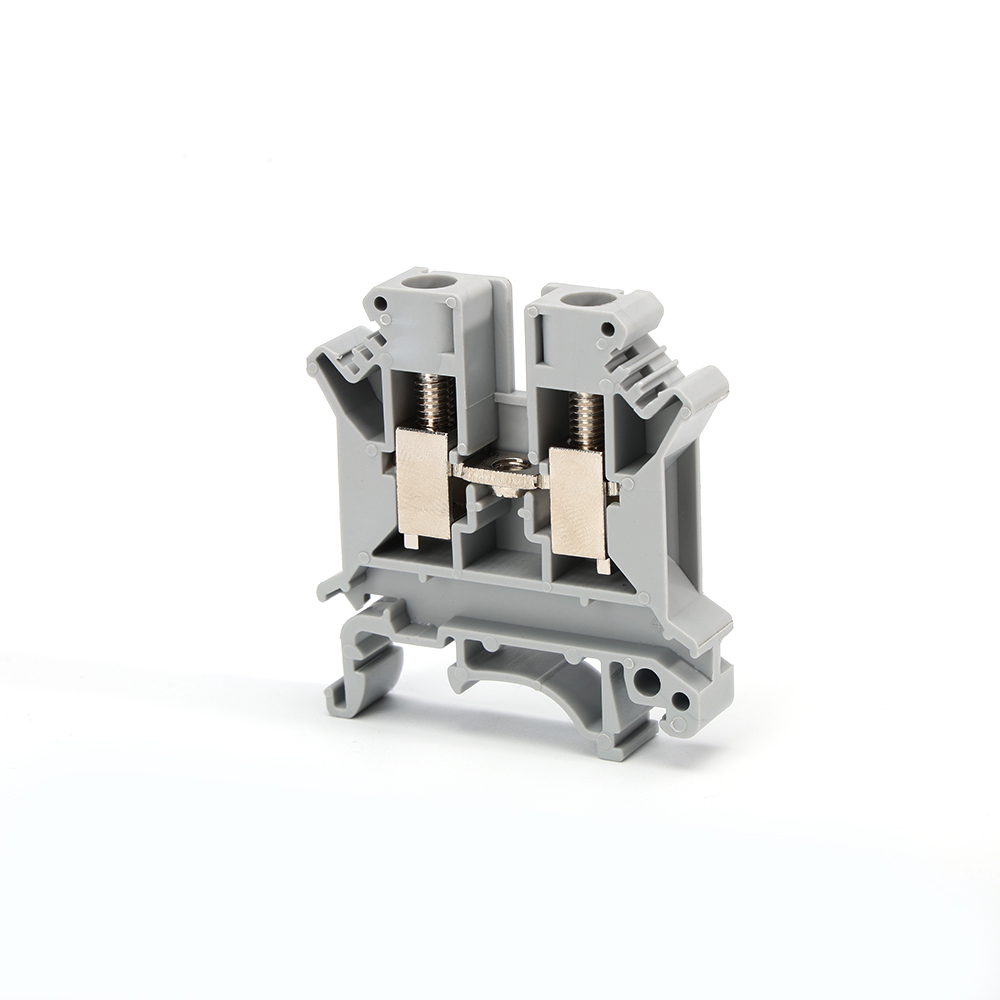

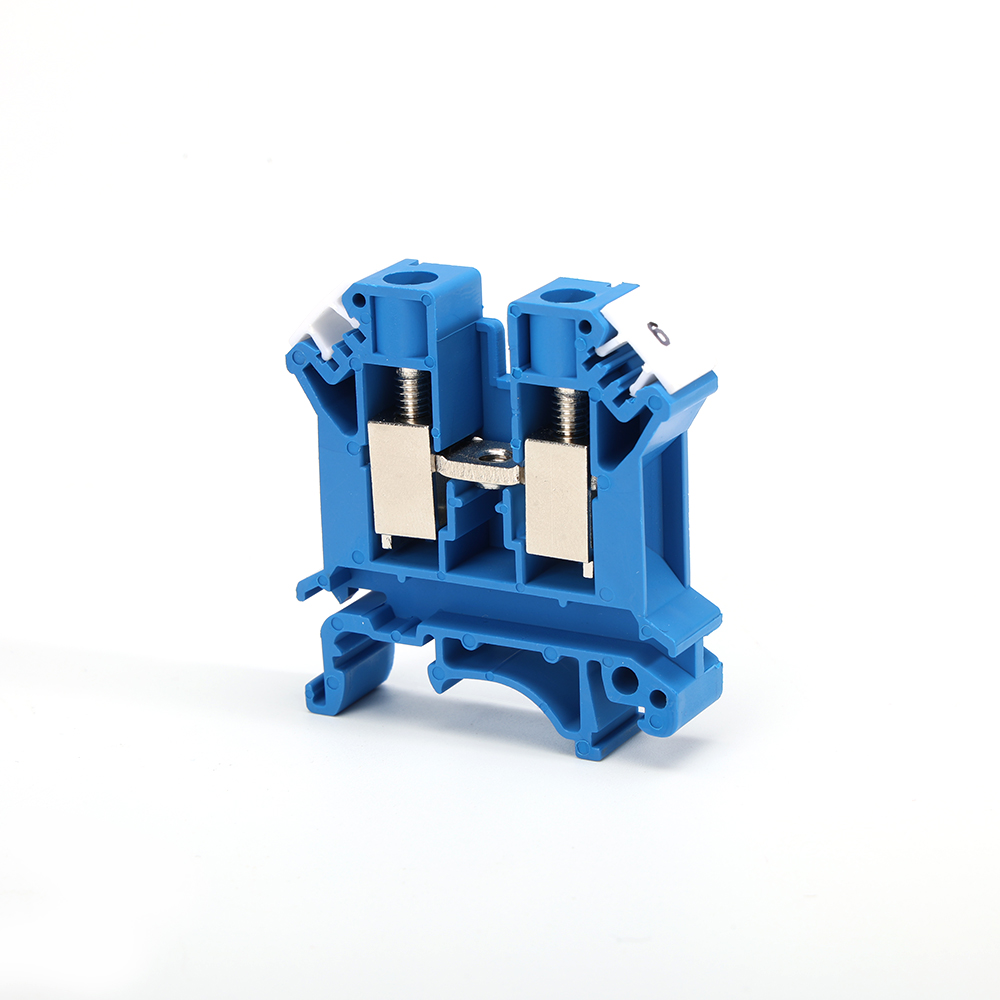

Screw Terminal Block

Advantages: Intuitive and reliable connection, low contact resistance, visible torque, wide range of applicable wire sizes (especially large cross-sections and solid wires), and generally lower cost.

Disadvantages: Slow installation speed, requires periodic tightening checks (weak vibration resistance), and requires space for screwdriver operation.

Screw terminal block suitable for: High-current power supplies, solid wires, applications that do not require frequent modifications, and cost-sensitive applications.

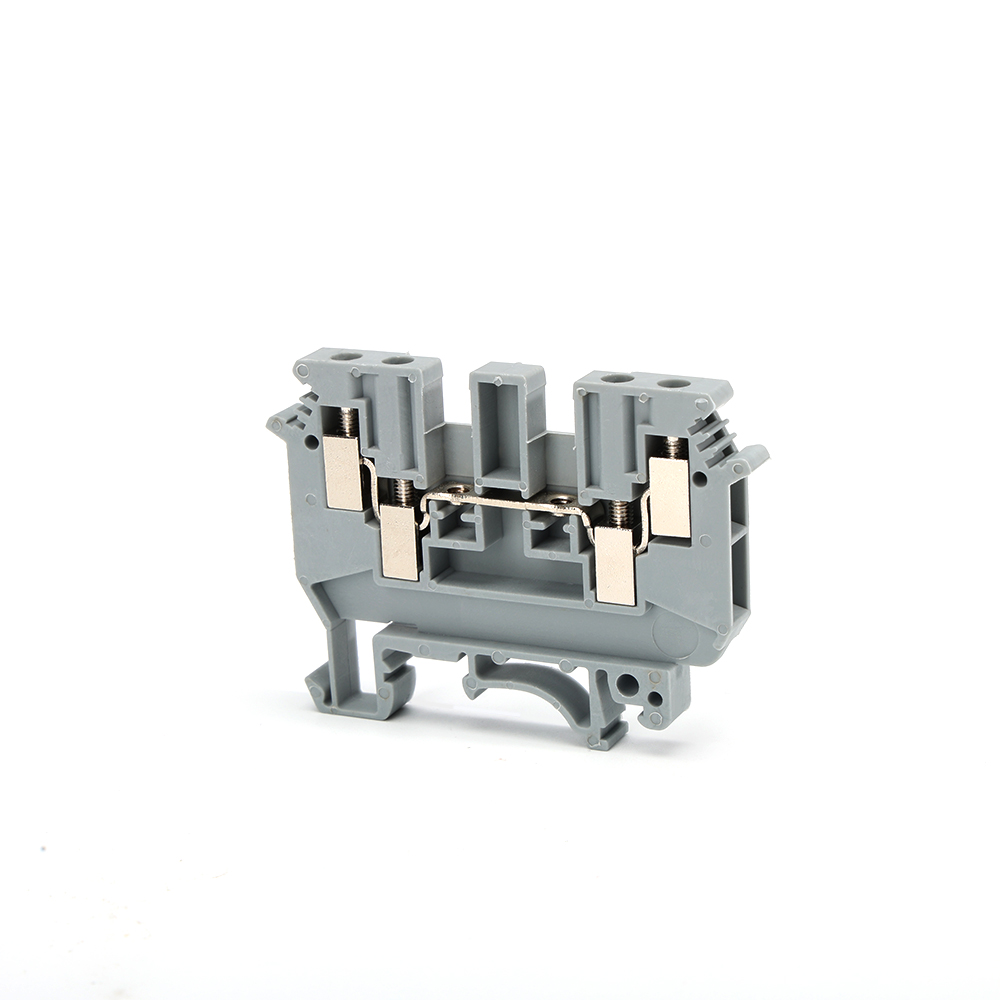

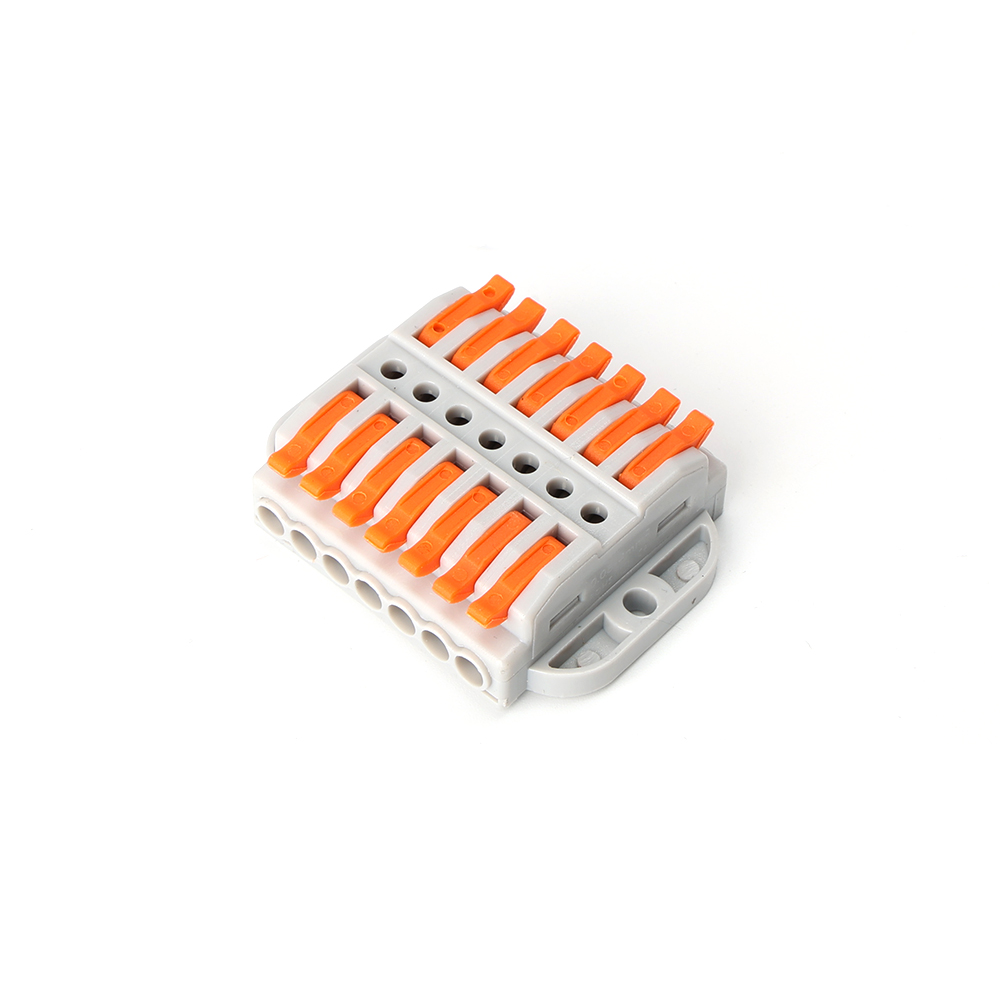

SpringTerminal Block

Advantages: Extremely fast installation, maintenance-free, excellent vibration resistance, space-saving, suitable for multi-strand fine wires.

Disadvantages: Initial investment is usually higher, requires specific tools (such as crimping tools), and is not suitable for very large cross-section wires.

Spring terminal block applications: Control signal lines, multi-strand flexible wires, high-vibration environments, and applications requiring frequent modifications or high-density installations.

Dedicated Function Terminals

In addition to general-purpose types, there are many specialized DIN rail terminal blocks, such as fuse terminals, disconnect switch terminals, relay terminals, and grounding terminals. These integrated solutions should be prioritized when your circuit requires specific electrical functions or safety isolation.

FAQ

Is The Spacing Between Terminal Blocks Important?

Extremely important. Electrical clearance and creepage distance must meet equipment safety standards (such as IEC/UL standards) to prevent arcing or short circuits. In high-voltage applications, terminals with sufficiently wide spacing must be selected.

How To Choose Terminals For Single And Multi-Strand Wires?

Single-strand solid wire: Screw terminals are the ideal choice, as their pressure effectively secures the wire.

Multi-strand flexible wire: Spring terminals are preferred, as their “cage spring” or “butterfly spring” evenly wraps around all the fine strands, preventing them from spreading apart. If screw terminals are used, wire ferrules or crimp connectors must be used.

Which Terminal Selected For High Vibration Environments?

Spring terminals are the preferred choice for high-vibration environments (such as rail transportation and heavy machinery) due to their constant contact pressure. Their screw-free design ensures reliable connections over the long term.