Terminals, as fundamental components in electrical connections, are found in distribution boxes, control cabinets, and various industrial equipment.

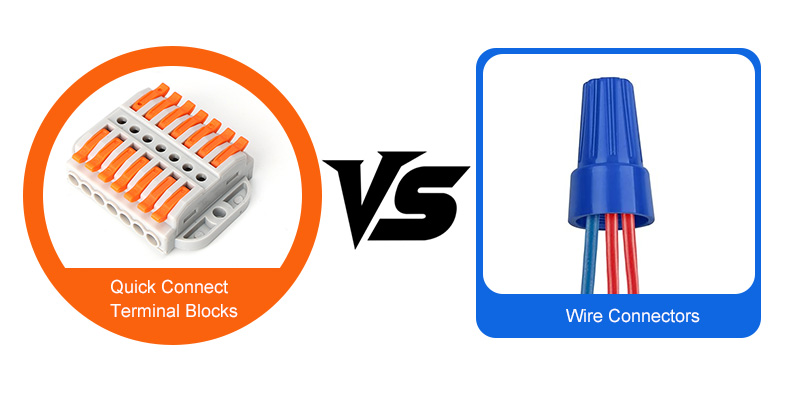

Faced with the mainstream terminal block spring and screw terminal blocks on the market, many engineers and installers are often confused when making a choice.

This article will delve into the core differences between the two and provide you with practical selection guidelines.

What Is Difference Between Spring And Screw Terminal Block

Purpose

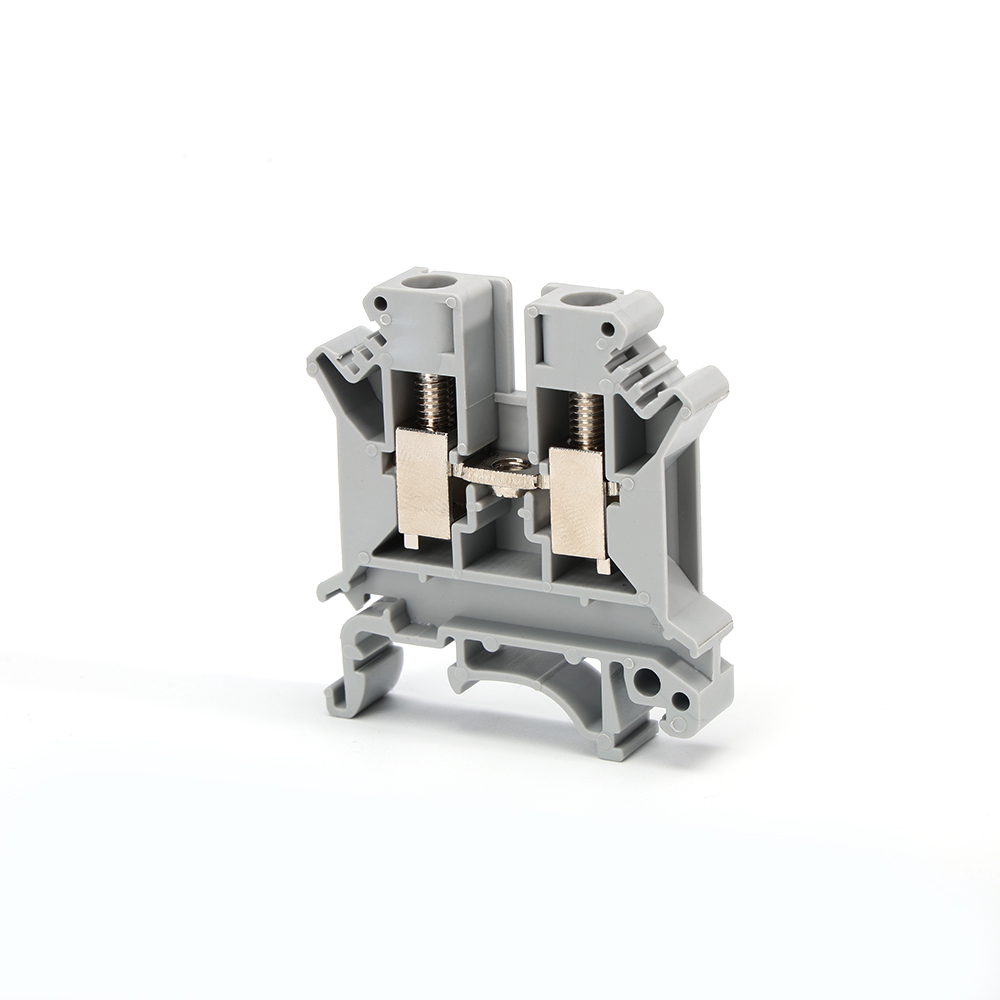

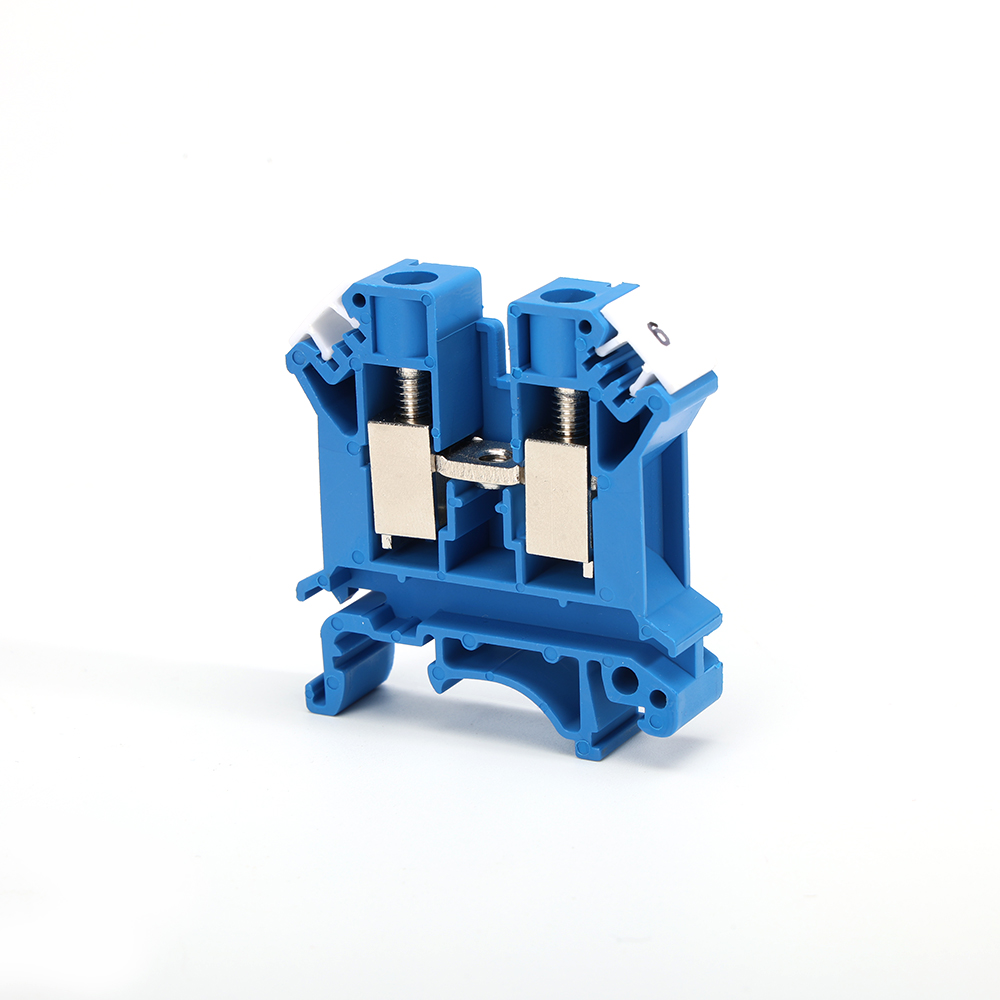

What is the purpose of a terminal block? Screw terminals represent traditional connection technology, relying on the mechanical pressure of screws to directly clamp the wires. Their design is simple and straightforward.

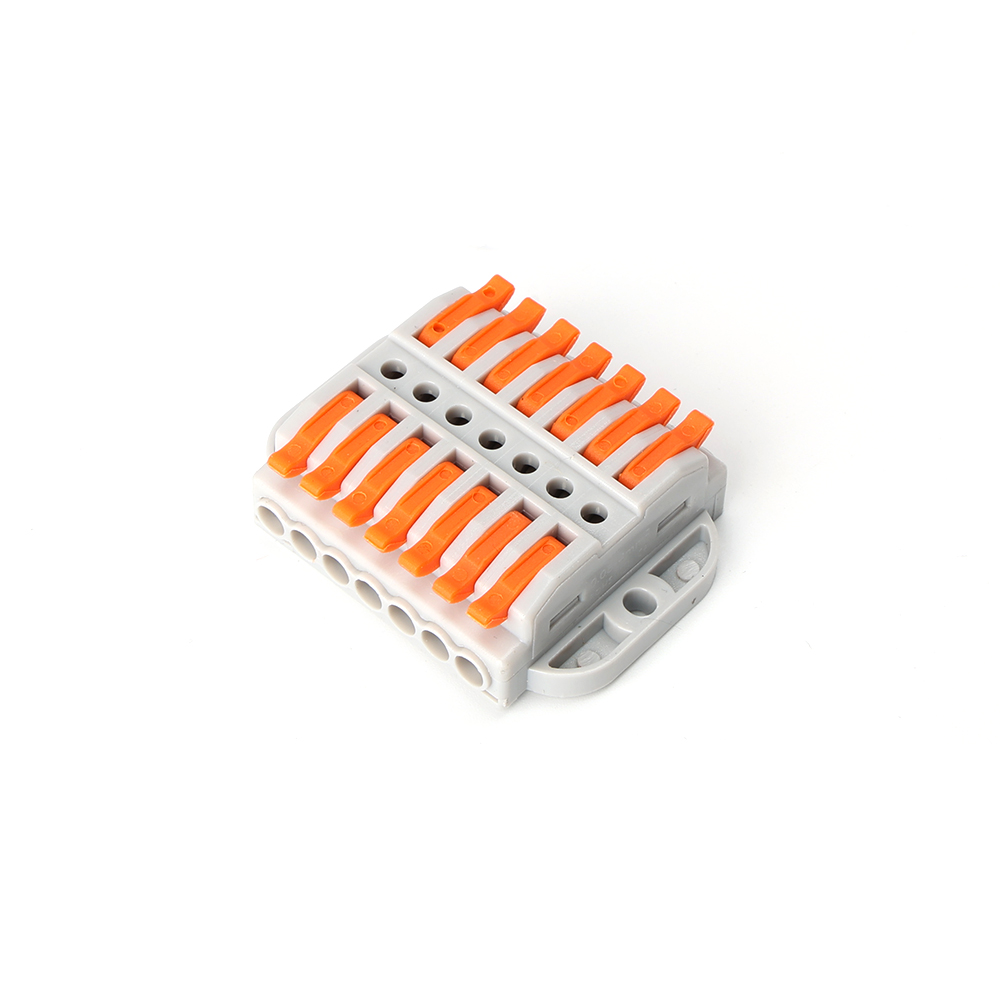

Spring terminals, on the other hand, utilize a modern connection concept, employing pre-compressed springs to generate constant pressure. Their design focuses more on quick installation and long-term reliability.

Operating Principle

Screw terminals generate downward pressure by rotating a screw, causing the conductive clamp to tightly grip the wire.

Spring terminals, on the other hand, have a built-in precision spring mechanism. When a wire is inserted, the spring is released by a special tool or by directly pushing the operating lever, generating a continuous and uniform clamping force.

Performance

Contact resistance: Due to constant pressure, spring terminals typically maintain a more stable and lower contact resistance.

Long-term stability: Spring terminals have better compensation capabilities for thermal expansion and contraction of materials caused by temperature cycling.

Corrosion resistance: The enclosed nature of the spring system reduces the impact of oxidation on the contact points.

Vibration Resistance

This is a significant advantage of spring terminals. In transportation equipment, rail transit, or industrial environments with mechanical vibrations, the continuous pressure from the spring effectively prevents screws from loosening, greatly improving connection reliability.

Wiring Speed

Spring terminals typically support fast wiring with tools, especially when using dedicated push-in tools. Wiring speed can be increased by more than 50% compared to traditional screw terminals, significantly reducing installation time.

Installation Skill Requirements

Screw terminals require installers to judge the appropriate tightening torque based on experience; insufficient or excessive torque can lead to malfunctions. Spring terminals offer a more standardized installation process, reducing reliance on individual skills and providing better consistency.

Conductor Type

Screw terminals have good compatibility with single-strand solid wires and multi-strand wires with crimped terminals. Spring terminals are particularly suitable for directly connecting fine multi-strand wires (without the need for crimping terminals) and can reliably secure wires as thin as 0.08mm².

Application Scenario

Spring terminals: More suitable for applications with vibration requirements, frequent maintenance and modifications, limited installation space, or where efficient installation is desired, such as PLC modules, building automation, and lighting systems.

How To Use Spring Terminal Block?

Preparation: Use wire strippers to strip the insulation from the wire to the appropriate length (usually 10-12mm).

Opening the spring: Insert a standard screwdriver into the operating hole and gently press down until you hear a “click,” indicating the spring mechanism is open.

Inserting the wire: Insert the stripped wire straight into the terminal hole until it reaches the bottom.

Releasing the spring: Remove the screwdriver; the spring will automatically reset and securely clamp the wire.

Checking: Gently pull the wire to confirm a secure connection. Some brands of terminals have a visual inspection hole.

FAQ

Can They Be Mixed And Used In The Same Cabinet?

Yes. In practical electrical cabinet design, a combination of terminal types is often used depending on the circuit characteristics. For example, screw terminals are used for high-current, infrequently modified circuits such as main power supply lines, while spring terminals are used for signal and control lines that require frequent testing and modification, balancing cost-effectiveness and ease of maintenance.

Which Is More Reliable, Spring Terminals Or Screw Terminals?

Reliability depends on the application environment. In static environments with stable temperature and humidity, both types of terminals are reliable when properly installed. However, in dynamic environments with vibration, thermal cycling, or corrosive gases, spring terminals generally exhibit higher long-term reliability due to their constant contact pressure and better sealing.

Terminal Block Spring Vs Screw Terminal Block Cost Analysis

In terms of initial procurement costs, spring terminals are typically 20%-40% more expensive than screw terminals of the same specifications. However, considering factors such as reduced installation time, ease of maintenance, lower failure rates, and life cycle costs, the total cost of ownership (TCO) of spring terminals is often more advantageous in many application scenarios.

Will Spring Terminal Lose Its Elasticity After Prolonged Use?

High-quality spring terminals utilize special alloy springs whose fatigue life is rigorously tested (typically reaching thousands of operating cycles). Under normal operating conditions, their elasticity remains stable throughout the entire lifespan of the equipment. Choosing reputable brands and avoiding exceeding specifications are crucial.

If I Need To Frequently Replace, Which One Is Better?

For circuits that require frequent plugging, testing, or modification (such as laboratory equipment and production line debugging interfaces), spring terminals are a superior choice. Their quick, tool-free operation and elimination of the need for repeated screw tightening significantly improve work efficiency and reduce the risk of stripped threads.

Which One Should Be Chosen For High Current Applications?

Both types have high-current specifications. For high currents (such as 100A and above), screw terminals have traditional advantages in heat dissipation design and controllable torque. However, in recent years, spring terminal technology specifically designed for high currents has also matured, and its constant pressure characteristics help reduce connection loosening caused by thermal cycling. When selecting, you should compare product specifications specifically, rather than judging solely based on the type.

Conclusion

What is the difference between a spring and a screw terminal block? Choosing between spring terminals and screw terminals is essentially a trade-off between initial cost and long-term performance, installation efficiency, and connection reliability. Screw terminals are a mature technology, inexpensive, and suitable for static, low-frequency applications.

Terminal block spring, on the other hand, are gaining increasing importance in modern electrical connections due to their higher installation efficiency, excellent vibration resistance, and ease of maintenance.