In the field of electrical connections, engineers, electricians, and DIY enthusiasts continually face the challenge of selecting the most suitable connection method. Among the most common solutions are quick-connect terminal blocks and traditional wire connectors (such as screw-type, crimp-type, or insulation-piercing connectors).

This article will explore the characteristics of quick connect terminal blocks and traditional wire connectors, offering a comprehensive comparison across multiple dimensions, including installation speed, reliability, cost, and flexibility, to help you make an informed decision for your next project.

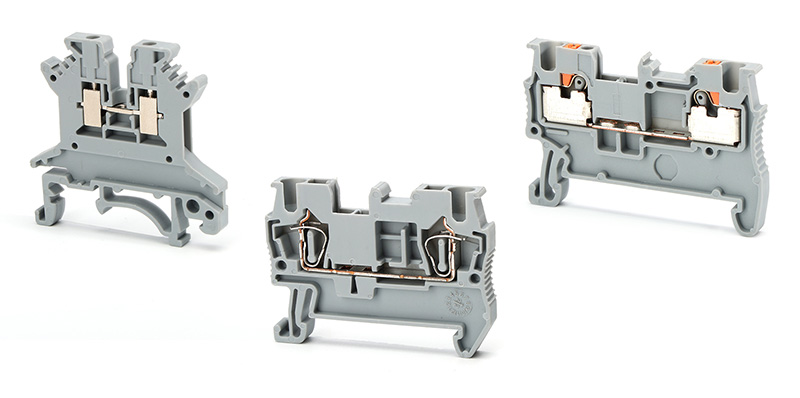

What Is A Quick Connect Terminal?

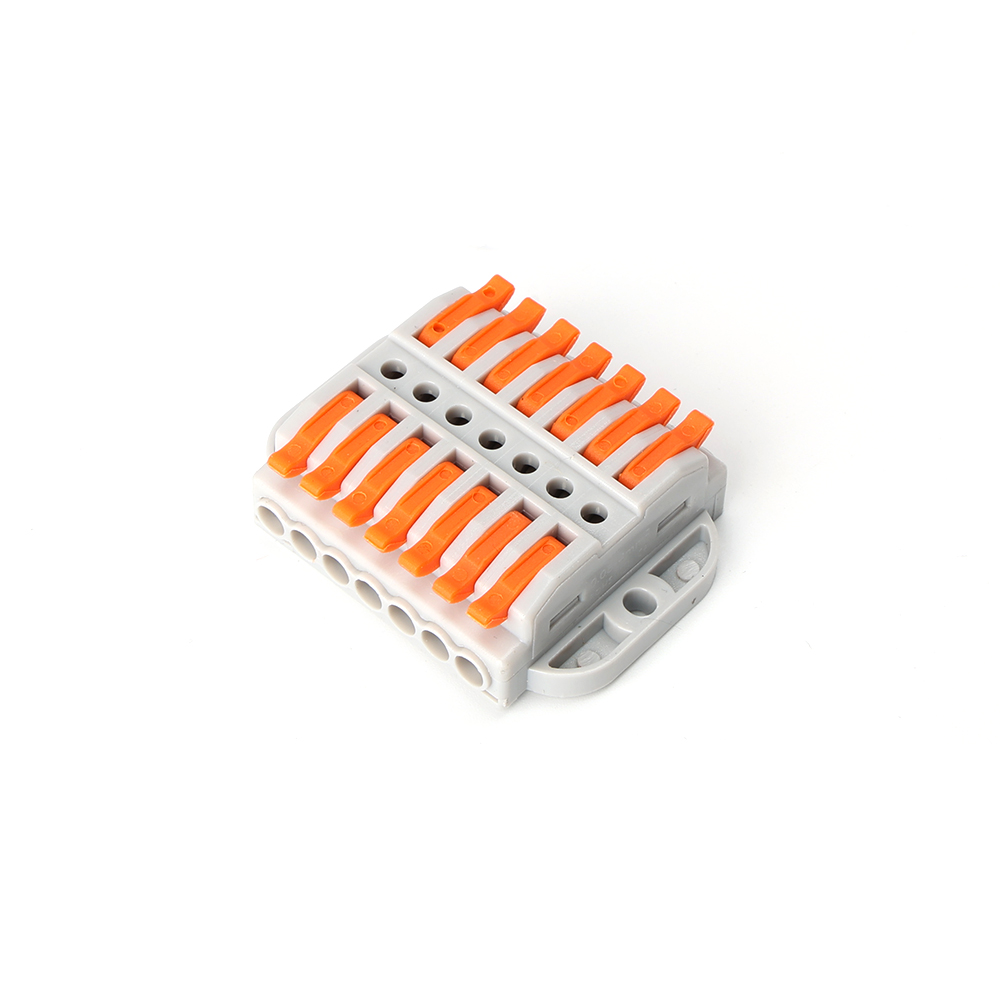

Quick-connect terminal blocks typically refer to modular wiring devices that allow for quick connection and disconnection of wires without the need for tools (or with only simple tools such as a screwdriver). The most common forms are spring-loaded terminals or push-in terminals.

Are Terminal Blocks Better Than Wire Connectors?

This is a core comparison problem. We will analyze it from multiple dimensions:

Installation Speed

Quick-connect terminal blocks: The winner. Their “plug-and-play” feature makes installation extremely fast, especially suitable for large-scale wiring, significantly reducing labor time.

Traditional wire connectors: Typically require additional steps such as tightening screws, using crimping tools, or twisting and insulating wires, which is more time-consuming.

Reuse Rate

Traditional wire connectors: Most (such as crimp caps and insulation displacement connectors) are for single use, and usually require replacement with new connectors after removal.

Wiring Density

Quick-connect terminal blocks: The winner. Typically installed in compact, modular rail-mounted form, they allow for very high-density, neat arrangement in limited spaces, saving control cabinet space.

Traditional wire connectors: Relatively bulky, with scattered connection points, they can appear messy in high-density wiring applications and occupy more space.

Visualization/Detection

Quick-connect terminal blocks: The winner. The connection points are typically open or semi-open, allowing for visual inspection of the connection status. Some designs even feature transparent housings to allow observation of whether the wires are properly inserted.

Traditional wire connectors: The connection points are completely enclosed, making visual inspection impossible without damaging the connector.

Long-Term Maintenance

Traditional wire connectors: Screw-type connectors may loosen due to vibration, and crimp-type connectors require cutting and re-crimping if they age, making maintenance relatively troublesome.

Applicable Wire Diameter/Type

Traditional wire connectors: More flexible. A wide variety of types are available, from those for thin wires to large cross-section cables, and even specialized connectors for different materials (such as copper-aluminum transitions).

Quick-connect terminal blocks: Usually have strict specifications regarding wire diameter range and are primarily suitable for single-core wires or multi-strand wires with crimped terminals. Wires that are too thin, too thick, or untreated fine multi-strand wires may not be suitable.

Scenario Analysis

Industrial control cabinets and distribution boxes: Terminal blocks are the absolute mainstream choice due to their neatness, ease of maintenance, and vibration resistance.

Home renovation and fixed wiring: Wire connectors (such as wire nuts and WAGO lever terminals) are more common due to their low cost and flexible installation.

Equipment interiors and frequently modified wiring (such as stage lighting and laboratories): Quick connectors offer a significant advantage due to their reusability.

High current and harsh outdoor environments: Specialized heavy-duty connectors or crimp terminals may be required.

How To Use Quick Connect Terminal?

Preparing the wires: Strip the insulation from the wires to the appropriate length according to the terminal specifications. For stranded wires, it is recommended to use crimp connectors.

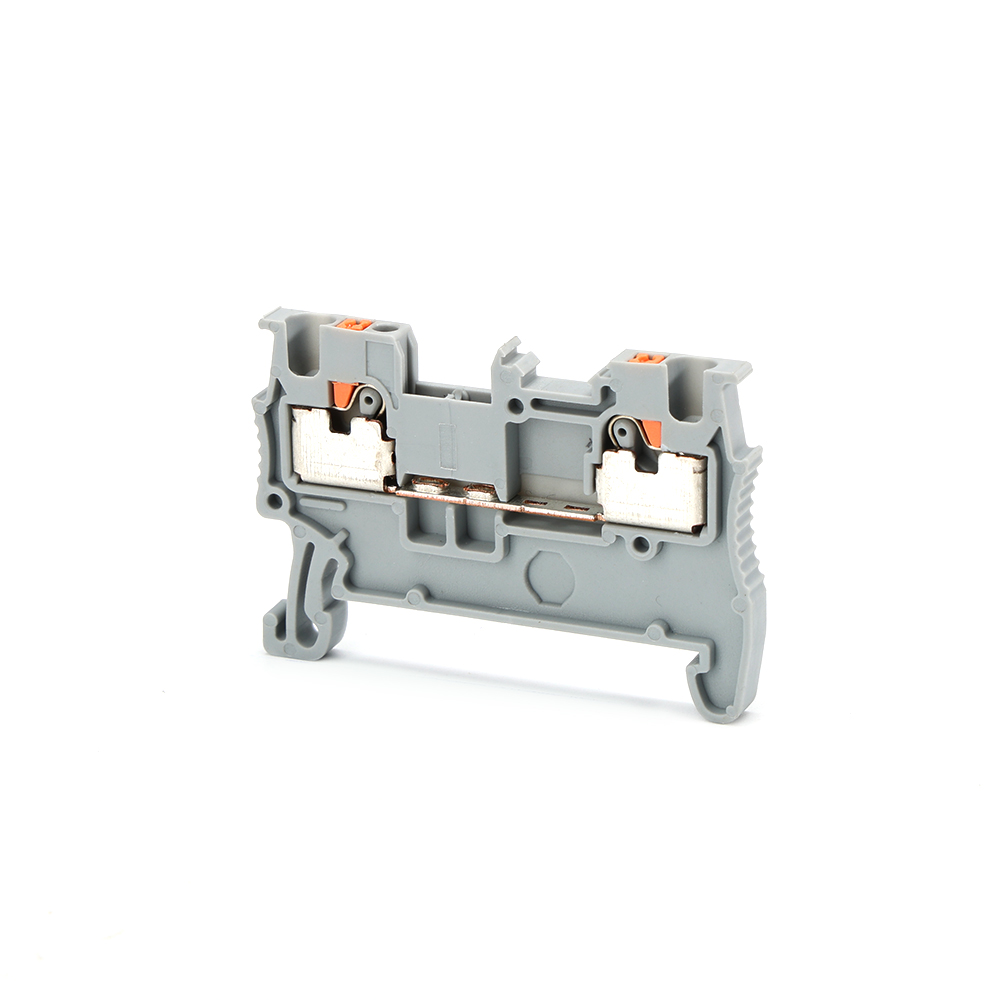

Preparing the terminals: If necessary, snap the terminal block onto the standard DIN rail.

Inserting the wires: Use a small screwdriver or a specialized tool to press/open the spring clip’s operating hole, fully insert the prepared wire into the hole, and then release the tool. A “click” sound or a feeling of being locked in place indicates that it is properly seated.

Checking: Gently pull the wire outwards to confirm that it is securely clamped.

How To Connect Wires In Terminal Block?

The quick connect wire connector manufacturer tells you,terminal blocks primarily offer two connection modes:

Single connection: Each terminal point independently connects to one incoming or outgoing wire.

Bridging/Jumpering: Using bridging connectors or short jumpers inserted between adjacent terminals, electrical continuity can be achieved between multiple terminals, used for distributing power or signals.

FAQ

Which Connection Has Higher Reliability And Security?

Both methods can achieve high reliability when installed correctly. Terminal blocks are generally superior in terms of vibration resistance and long-term stability. The reliability of wire connectors, however, is highly dependent on the quality of installation (e.g., crimping torque, number of twists). From a safety standards perspective, products that comply with international standards (such as UL and IEC) are considered safe.

Which One Is Faster In Terms Of Installation Speed?

Undoubtedly, quick-connect terminal blocks offer significantly faster installation than most traditional wire connectors, especially when connecting a large number of wires.

From A Cost Perspective, How Should We Make A Choice?

Unit Price: The cost of a single traditional wire connector (such as a wire nut) is extremely low.

Total Cost of Ownership: Considering installation time, ease of maintenance, and the risk of downtime due to failures, the long-term benefits of terminal blocks in industrial projects often outweigh their higher initial material costs. For one-time, small-scale applications, traditional connectors are more economical.

How To Make A Choice Based On My Specific Project?

Ask yourself a few questions:

Do you need to make frequent changes? Yes → Choose terminal blocks.

Is space limited and wiring dense? Yes → Choose terminal blocks.

Is the environment subject to vibration? Yes → Choose spring-type terminal blocks.

Is it a one-time, low-cost home improvement project? Yes → Choose reliable wire connectors or lever terminals.

Are the wire types special or complex? Yes → Evaluate specialized wire connectors.

Who Has The Advantage In Terms Of Flexibility?

Traditional wire connectors offer greater flexibility in terms of on-site adaptability and handling various wire types. Quick-connect terminal blocks, on the other hand, offer greater flexibility in terms of systematic wiring, scalability, and subsequent modifications.

Conclusion

Quick-connect terminal blocks excel in installation efficiency, maintainability, neatness, and long-term stability, making them ideal for industrial control, complex systems, and applications requiring frequent adjustments.

Traditional wire connectors, on the other hand, offer advantages in cost-effectiveness, wide applicability, and handling specific wire types, making them particularly suitable for fixed installations, small-scale projects, or budget-sensitive applications.

Still hesitating about the connection options for your project? Our team of experts will leverage their extensive field experience to provide you with free professional analysis and precise product recommendations.