As someone working in industrial operations, you’re probably well aware that the quality and reliability of a seemingly small component—such as a copper pipe terminal—often directly impacts the stability and safety of the entire system. Choosing the right manufacturer and the right tools is no small matter; it’s a crucial step in optimising processes and eliminating potential problems. Today, copper tube terminal manufacturers discuss how to make smart and efficient choices in this area.

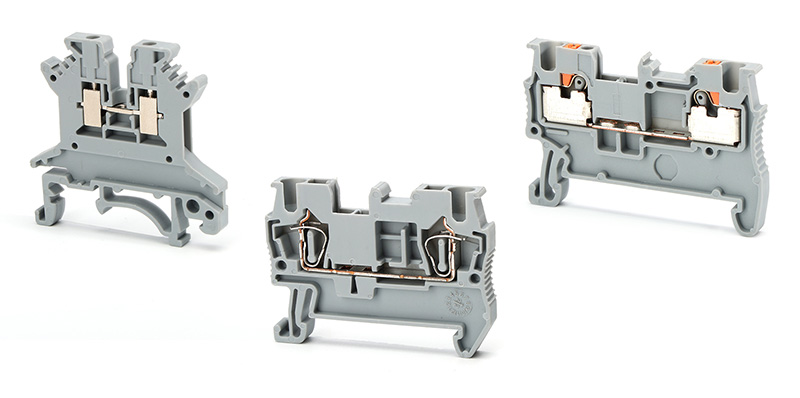

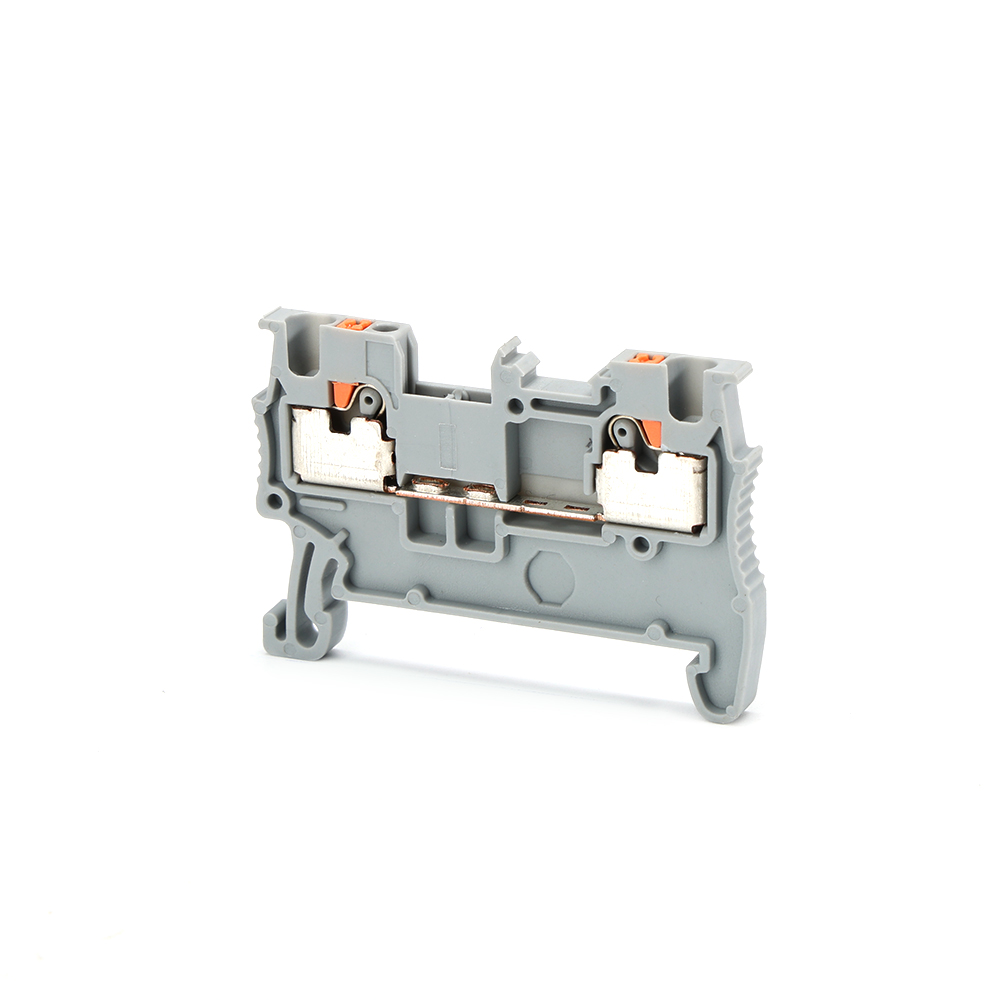

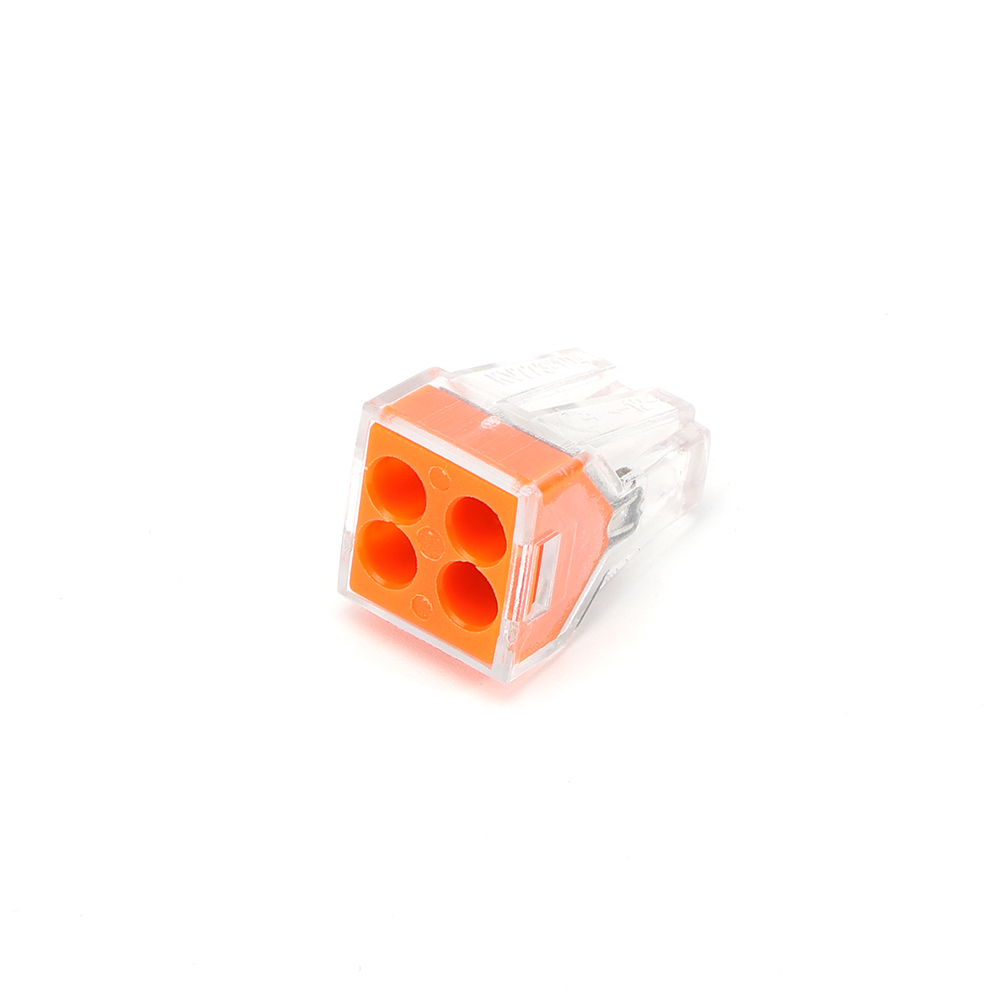

What Is Copper Tube Terminal?

Copper conduit terminals are metal sleeves used for connecting the ends of electrical wires. They are typically made of high-quality copper, which has excellent conductivity and ductility. Through crimping, they securely bundle and connect loose wire cores to screw terminals or rails, providing a stable, low-resistance, and durable electrical connection. They are ubiquitous in fields such as power, electrical control, rail transportation, and new energy, truly serving as “safety guardians.”

How To Choosing Copper Tube Terminal Manufacturer

Core Manufacturing Process Flow

A reliable manufacturer’s process goes far beyond a simple press-and-press job. A high-quality process typically includes: precision stamping to ensure dimensional accuracy; the selection and pretreatment of oxygen-free or low-oxygen copper to guarantee conductivity; crucial annealing (aging treatment) to give the terminals the perfect balance of hardness and flexibility, facilitating crimping while preventing cracking; and possibly tin plating to enhance corrosion resistance and solderability. You should know that the rigorous execution of these processes is the “inner strength” hidden behind the finished product.

How To Select High Quality Manufacturers

Here are a few key dimensions you should focus on:

Qualifications and Certifications: Adhere to high industry standards, such as ISO 9001 quality management system certification, and verify that products comply with international or industry standards like UL, VDE, and RoHS. This is the foundation of their capabilities.

Technical Capabilities and Quality Control: Don’t just rely on sample brochures. Ask if they have spectrometers to test raw material composition and professional tensile testing machines for finished product verification. A manufacturer willing to share their quality control processes and test reports is usually more trustworthy. For example, Westlec provides traceable material reports for each batch of products, and this transparency greatly increases confidence in cooperation.

Production Capacity and Consistency: When purchasing in large quantities, production capacity and quality stability are crucial. On-site visits or videos to understand their level of automation and workshop management often provide more authentic information than brochures.

Industry Reputation and Case Studies: Ask about their service experience in your industry. A copper tube terminal manufacturer with long-term stable supply cases in rail transit or new energy fields has likely already rigorously verified the environmental adaptability and reliability of their products.

Detailed Of Copper Tube Terminal Crimping Tools

Why Is It Necessary To Use Professional Crimping Tools?

Clamping with pliers carelessly? That’s a big no-no! Unprofessional crimping can lead to incomplete crimping (high resistance, overheating), over-crimping (damage to the wire core or terminal cracking), or incorrect crimping position—all potential safety hazards. Professional copper tube terminal crimping tools ensure precise pressure, consistent crimping depth, and perfect hexagonal or elliptical compression, achieving an airtight connection between metals like a cold weld, guaranteeing optimal conductivity and mechanical strength.

Types And Selection Of Crimping Tools

Manual Crimping Pliers

Suitable for: Small-batch, fine-diameter (e.g., 0.5-6mm²) routine maintenance or production.

Personal opinion: Economical and flexible, but entirely reliant on manpower, resulting in slightly lower consistency. For large-scale operations prioritizing efficiency and quality stability, it may not be the first choice.

Hydraulic Crimping Pliers (Manual/Electric)

Applicable Scenarios: The primary tool for crimping medium to large diameter wire terminals (e.g., 10-300mm² and above), especially suitable for power engineering and equipment installation.

Key Selection Points: Manual hydraulic systems are suitable for mobile on-site operations; electro-hydraulic systems significantly reduce labor and improve efficiency. The key is whether the molds are complete and precise, as well as the durability of the pump body. This is a worthwhile investment in a labor-intensive solution.

Pneumatic/Electric Crimping Machine

Suitable Scenarios: The undisputed king of high-volume, assembly line production environments.

Advantages: Simply step on the pedal or press a button to achieve consistent, perfect, high-quality crimping, greatly reducing labor intensity and increasing productivity and quality control. If your production pace is fast, this is practically a must-have.

Crimping Operation Procedure And Quality Judgment

Preparation: Select the correct terminal type and matching crimping die. The length of the stripped wire insulation must be precise.

Insertion: Fully insert the exposed wire core into the copper tube terminal sleeve until the tip touches the bottom.

Crimping: Place the terminal in the correct position on the die (usually slightly towards the cable insulation side in the middle of the sleeve) and crimp. A “click” sound or reaching the set pressure indicates completion.

Quality Inspection:

Visual Inspection: The crimped area should be a regular, symmetrical hexagon or ellipse, without excessive deformation or cracking.

Touch Inspection: The wire should not be easily pulled out or twisted from the terminal.

Cross-section Analysis (for high standards): The crimped cross-section should show no gaps between the wire cores and a tight bond with the terminal sleeve wall.

Industry Application Practice And Selection Guide

Selection Focus Of Different Industries

Power Distribution Industry: Current carrying capacity and long-term temperature rise are primary considerations, leading to the use of large-diameter, thick-walled, tin-plated terminals. Heavy-duty hydraulic tools are the mainstay.

Rail Transit: Vibration resistance and reliability are extremely important. Terminal materials and crimping quality requirements are very high, often necessitating fully automated crimping with 100% inspection.

Automation Equipment and Control Systems: Compactness and consistency are emphasized. Small-diameter terminals are widely used, and pneumatic/electric crimping machines offer significant advantages on assembly lines.

New Energy (Photovoltaic/Energy Storage): Facing challenges of outdoor environments, high current carrying capacity, and large temperature differences, corrosion protection (e.g., tin plating) and connection reliability of terminals are crucial.

Comprehensive Selection Decision List

Before making a final decision, consider asking yourself the following questions based on this checklist:

What are my application scenarios and wire gauge ranges?

What is the expected crimping volume (daily/monthly)?

What are the required levels of connection consistency and reliability? (Normal/High/Extremely High)

Does the working environment (workshop/field) require portability of tools?

What is the budget range? (Consider long-term return on investment)

FAQ

How To Quickly Determine Reliability Of Copper Tube Terminals?

Check the appearance for smoothness and burr-free surfaces; squeeze them (after annealing) for a certain degree of toughness and resistance to cracking; check the markings and accompanying material/test reports for clarity and completeness. Manufacturers like Westlec, which focus on branding, usually have very standardized product labeling and traceability information.

How To Choose Manual, Hydraulic, Pneumatic/Electric Crimping Tools?

Consider both quantity and quality. Choose manual for minor repairs, hydraulic for medium to large projects or regular production, and for high-efficiency, consistent mass production, choose pneumatic/electric without hesitation.

How To Determine If The Crimping Joint Is Of Acceptable Quality?

The most direct, “basic” method: After performing a pull-out test (pulling the wire and terminal with appropriate force), cut open a crimped joint to check if the internal wire core is firmly compressed into a single unit without gaps. Of course, a professional pull-out test is the gold standard.

Can Copper Tube Terminals Be Reused After Crimping?

Absolutely not recommended. Crimping is a plastic deformation process; disassembly will damage the structure, and re-crimping cannot guarantee the original performance, posing safety hazards.

Tube Terminal Vs Ordinary Cable Terminal

What is the difference between copper tube terminals and ordinary cable terminals?The main difference lies in the “tube” structure. Copper tube terminals are more suitable for bundling and crimping multi-strand flexible wires, have a larger crimping area, and are generally more reliable than ordinary terminals that rely solely on screws and clips.

Conclusion

Choosing the right copper terminal blocks and their perfect partner—the crimping tool—is a delicate collaboration concerning quality, efficiency, and safety. From understanding the mindset of a meticulous copper terminal block manufacturer to equipping the right crimping tool for different tasks, every step deserves your careful consideration.

Are you tired of tracing the root cause of equipment failures and safety hazards only to find the problem lies at a small connection point? It’s time to upgrade your connection standards. We sincerely invite you to learn more about partners like Westlec, who prioritize quality and reliability. They not only offer a full range of copper terminal blocks that meet stringent standards but also provide professional solutions from product selection to crimping tool configuration. Act now to request free samples and product catalogs, or schedule a dedicated technical exchange.