Ever found yourself staring at a maze of wires in a control panel, wondering how to bring order to the chaos? That’s exactly where terminal blocks come in—they’re the unsung heroes of electrical systems, silently organizing, securing, and distributing connections. In simple terms, think of them as the reliable meeting points where wires safely connect, circuits get organized, and troubleshooting becomes a whole lot easier. For procurement specialists like you, choosing the right terminal block connector isn’t just about specs; it’s about ensuring long-term reliability, safety, and ease of maintenance. Let’s break down what they do and how to use them effectively, with a nod to why brands like Westlec make all the difference.

What Do Terminal Blocks Do?

Core Hub Of Electrical Connection

At their heart, terminal blocks are all about creating secure, reusable connections. Imagine you’re wiring an industrial machine—instead of twisting wires together and hoping for the best, you slot each wire into a dedicated terminal. It’s like giving every wire its own parking space. This not only prevents loose connections (a common fire hazard!) but also lets you modify or expand circuits down the line without starting from scratch. For example, in a Westlec-equipped panel, you can quickly swap out a sensor without disturbing the entire wiring layout—saving time and reducing downtime.

Circuit Organization And Modular Management

Chaos is the enemy of efficiency, especially in electrical cabinets. Electric terminal blocks act like librarians for your wires, grouping them by function, voltage, or signal type. Picture a manufacturing line’s control panel: power circuits, sensor signals, and communication lines all neatly separated into labeled blocks. This modularity means you can troubleshoot a faulty section without pulling apart the entire system. Westlec’s color-coded and numbered blocks take this further, making visual identification instant—a small detail that speeds up maintenance massively.

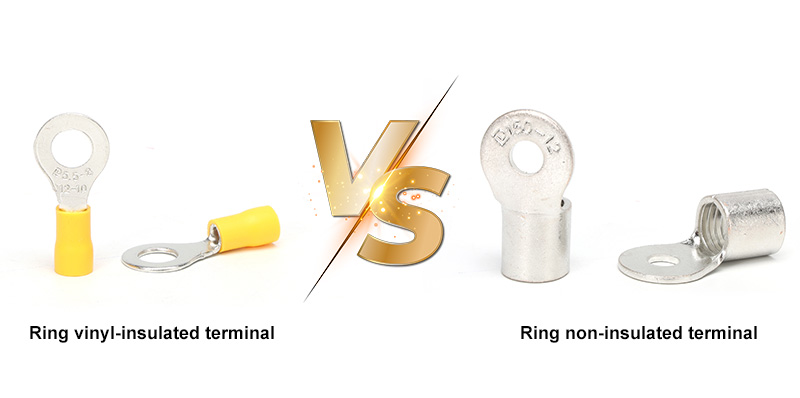

Safety, Isolation And Protection Functions

Safety isn’t just a checkbox; it’s a necessity. Connecting terminal blocks provide physical and electrical isolation between circuits. Think of a panel mixing 240V power and 24V control signals—using a single block for both? That’s asking for trouble. With isolated blocks, you prevent accidental contact, short circuits, and even electrical noise interference. In one case, a food processing plant avoided a major shutdown by using Westlec’s high-isolation blocks to separate wet and dry circuits, protecting sensitive equipment from moisture-induced failures.

Distribution Nodes For Signals And Power Supply

Need to split a single power source to multiple devices? Terminal blocks are perfect distribution points. They take one incoming wire and branch it out to several outputs, ensuring consistent voltage delivery. For instance, in an HVAC system, a single mains feed can be distributed to fans, pumps, and controllers via a terminal block connector. Westlec’s blocks with built-in fuse holders add an extra layer of protection—because overcurrents shouldn’t mean costly replacements.

Access Points For Testing And Troubleshooting

Let’s be honest: electrical faults happen. The beauty of terminal blocks is that they turn a nightmare into a manageable task. Each connection point is accessible, so you can probe with a multimeter or disconnect a circuit without cutting wires. Say a motor isn’t starting; instead of tracing wires through conduit, you check the terminals for voltage drop or continuity. Westlec designs blocks with test ports and transparent covers, making live testing safer and faster—something your maintenance team will thank you for.

How To Use Terminal Block?

Preparation Before Use

Before you even touch a wire, start with the basics. Choose the right block—match its current rating (like 20A or 60A) to your application, and consider factors like wire gauge, voltage, and environmental conditions (dust, humidity, etc.). Gather tools: a screwdriver, wire strippers, and maybe a torque driver for precision. Don’t forget to power down the system—safety first! Inspect the block for damage; a cracked insulator can lead to failures. Pro tip: Keep Westlec’s catalog handy; their blocks come with clear specs, making selection a breeze.

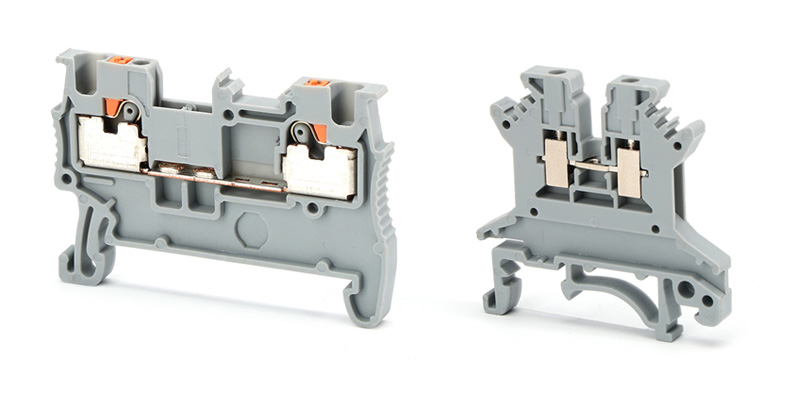

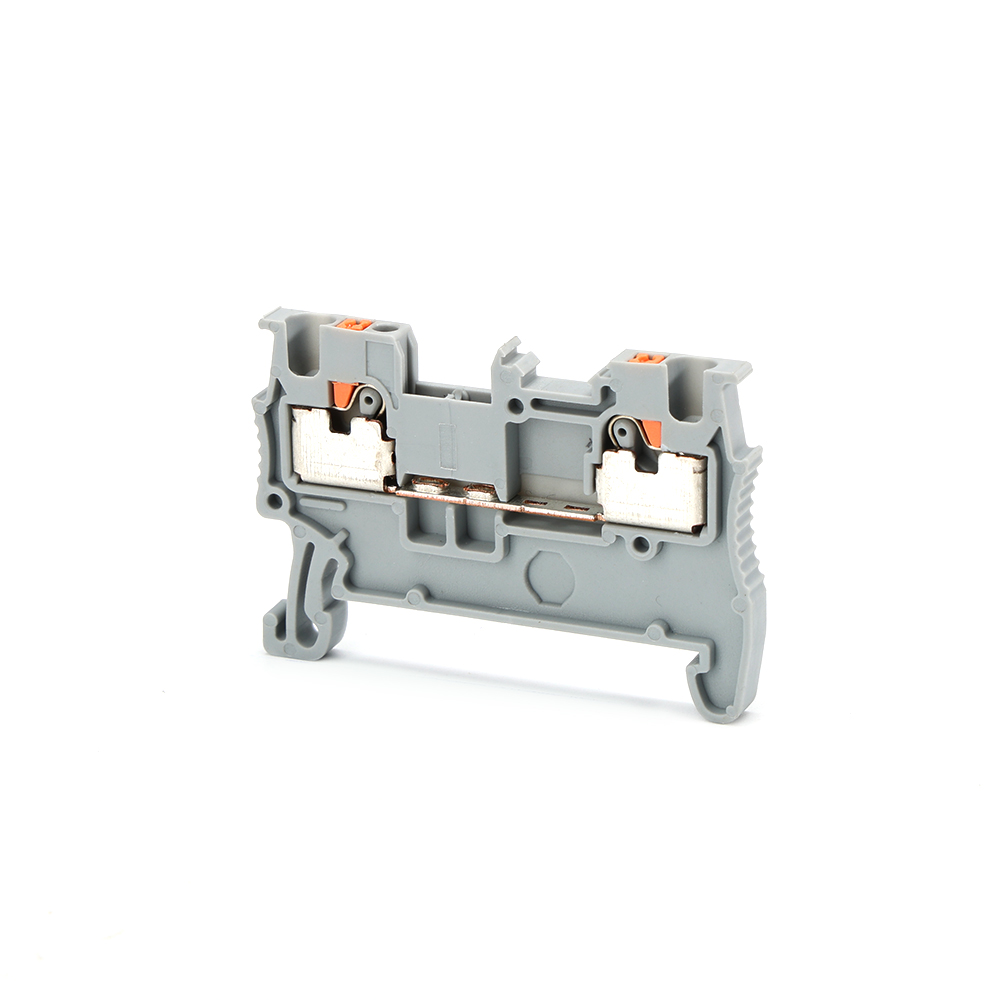

Detailed Explanation Of Standard Installation Steps

Strip the Wire: Expose just enough conductor—usually 8-10mm—to fit securely without stray strands. Too much bare wire risks shorts; too little means a weak connection.

Insert the Wire: Slide the stripped end into the terminal slot. For screw-type blocks, loosen the screw first, insert, then tighten. For spring-clamp types (like Westlec’s DIN rail mounts), just push in with a tool—it’s faster for high-volume jobs.

Secure the Connection: Tighten screws to the recommended torque (check the datasheet!). Over-tightening can strip threads; under-tightening causes overheating. Tug the wire gently to confirm it’s locked.

Organize and Label: Mount blocks on DIN rails, group by function, and label each terminal. Westlec offers pre-printed markers—because guessing games have no place in professional setups.

Final Check: Verify all connections are snug, insulators are intact, and no wires are crossing. Apply power gradually while monitoring for unusual heat or sparks.

FAQ

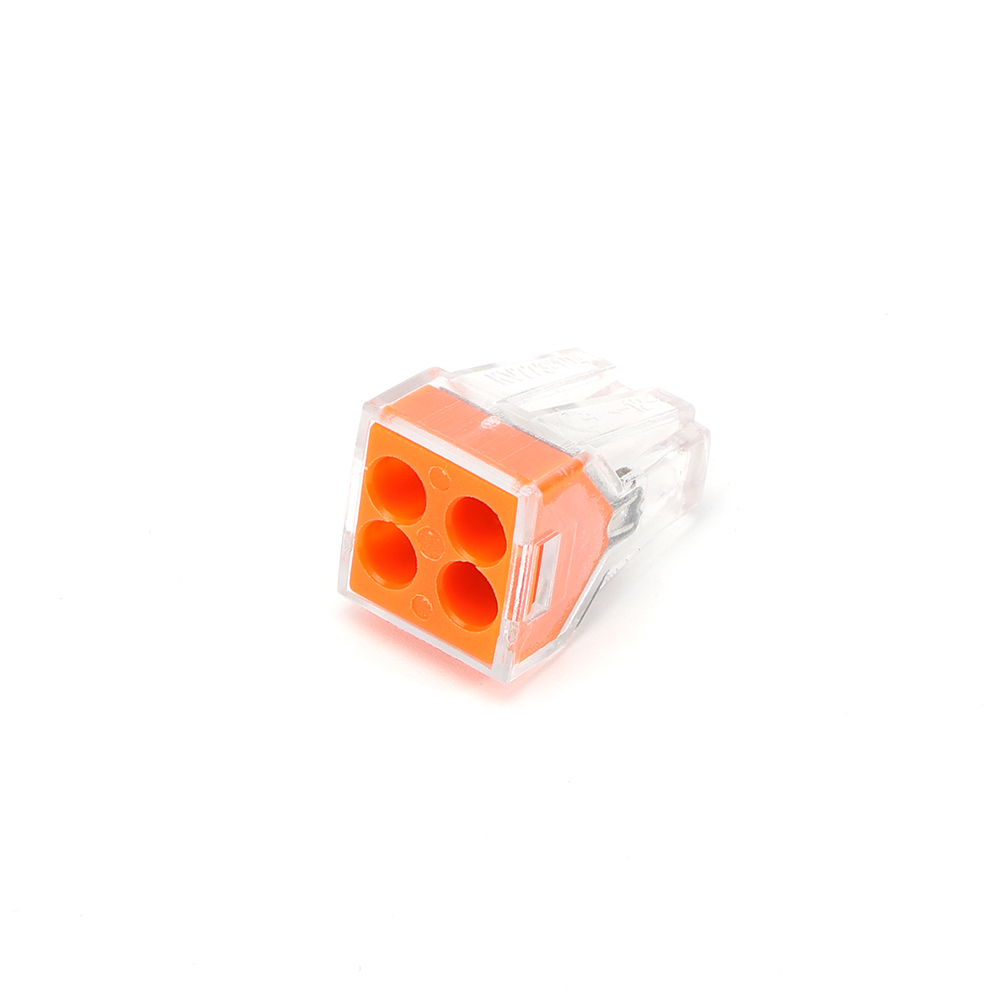

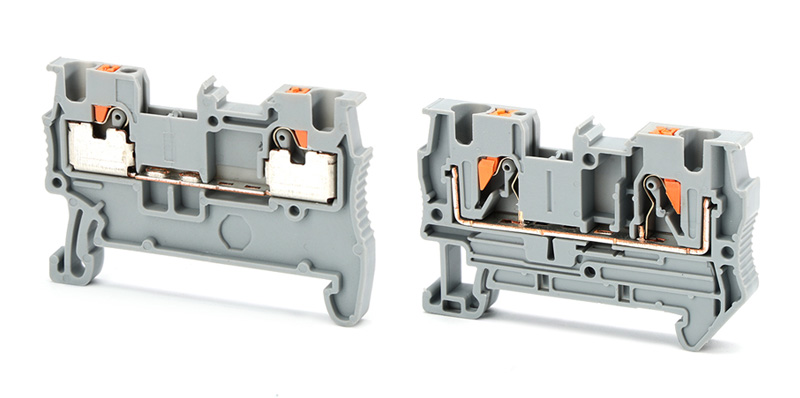

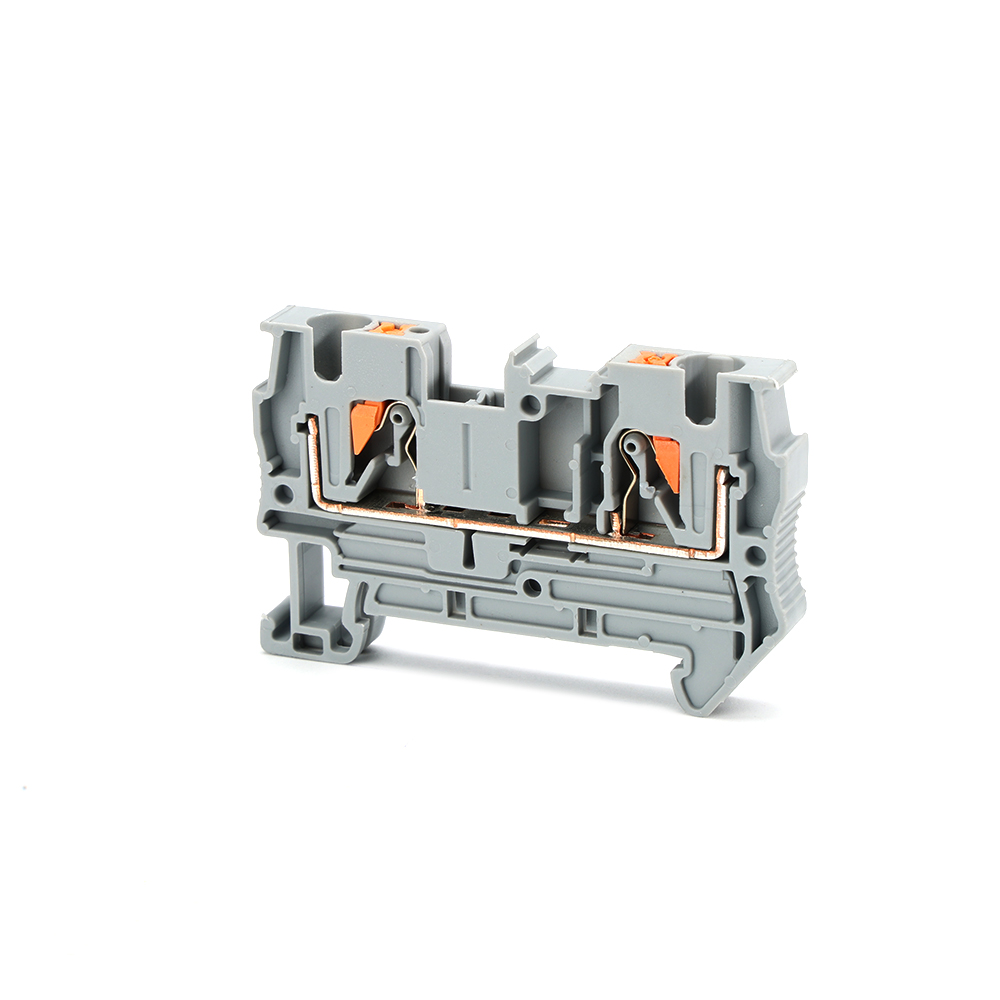

Terminal Block Connector Types

Common types include screw terminals (durable, for high current), spring-clamp (vibration-resistant, quick install), and push-in (tool-free, ideal for tight spaces). Westlec provides all three, so you can match the type to your need—like spring clamps for machinery prone to shaking.

How To Select The Appropriate Current Rating?

Always pick a rating above your system’s maximum expected current. For a 15A circuit, a 20A-25A block adds a safety margin. Check Westlec’s charts—they factor in ambient temperature and material conductivity, so you don’t gamble with undersized parts.

What Is The Importance Of The Spacing Between Terminal Blocks?

Spacing (or “pitch”) prevents arc-overs and heat buildup. In high-voltage apps, wider spacing (e.g., 10mm vs 5mm) is critical. Westlec blocks offer options here, helping you comply with safety standards effortlessly.

The Most Common Reason For Terminal Connection Failure?

Loose connections—from vibration or poor installation—are the top culprit. They cause arcing, overheating, and eventually, failure. Using torque tools and quality blocks like Westlec’s vibration-resistant designs mitigates this risk.

How To Prevent Terminal Overheating?

Ensure proper torque, use blocks rated for your current, and avoid mixing wire sizes in one terminal. Regular infrared inspections can spot hot spots early. Westlec’s copper-alloy terminals excel here, offering better heat dissipation than cheaper alloys.

Conclusion

Terminal blocks are more than simple connectors—they’re the backbone of safe, organized, and maintainable electrical systems. From distributing power to isolating circuits, their role is pivotal in everything from factory floors to building automation. And when it comes to reliability, details matter: the right material, precise engineering, and thoughtful design make all the difference. That’s where Westlec stands out—with decades of expertise, our blocks are built to endure, simplify installations, and keep your operations running smoothly. Because in procurement, you’re not just buying a component; you’re investing in peace of mind.

Ready to streamline your next project with confidence? Contact Westlec today for a customized consultation or to request free samples. Our team is here to help you select the perfect terminal block connector for your application—ensuring you get durability, safety, and value, without the guesswork. Let’s build something reliable together!